JIS SKD11 Cold Worked Mold Steel

JIS SKD11 is a versatile tool steel that offers a combination of high hardness, wear resistance, and toughness, making it a popular choice for a wide range of industrial applications.

JIS SKD11 is a high carbon, high chromium, and high vanadium tool steel that is commonly used in the manufacturing of cutting tools, molds, and dies. Its high hardness, wear resistance, and toughness make it suitable for applications that require high levels of abrasion resistance and cutting performance.

- HONGXING

- DAYE

- 30 DAYS

- 20000 TON/MONTH

- Information

JIS SKD11 Cold Worked Tool Steel

1: JIS SKD11 is a high carbon, high chromium, and high vanadium tool steel that is commonly used in the manufacturing of cutting tools, molds, and dies. Its high hardness, wear resistance, and toughness make it suitable for applications that require high levels of abrasion resistance and cutting performance. steel introduction

JIS SKD11 is a high carbon, high chromium, and high vanadium tool steel that is commonly used in the manufacturing of cutting tools, molds, and dies. Its high hardness, wear resistance, and toughness make it suitable for applications that require high levels of abrasion resistance and cutting performance. JIS SKD11 steel is an air hardening, high-carbon, high-chromium tool steel. It has high wear and abrasion resistant properties. It is heat treatable and will offer a hardness in the range 55-62 HRC, and is machinable in the annealed condition. JIS SKD11 steel shows little distortion on correct hardening. Cr12Mo1V1 steel’s high chromium content gives it mild corrosion resisting properties in the hardened condition.

If customer need better machinability, we recommend A2, because A2 has a chromium content of 5% and is more readily machinable.

2: JIS SKD11 steel application

JIS SKD11 tool steels are used for long run tooling applications, where wear resistance is important, such as blanking or forming dies, punches, forming rolls, knives, slitters, shear blades, tools, scrap choppers, tyre shredders and so on.

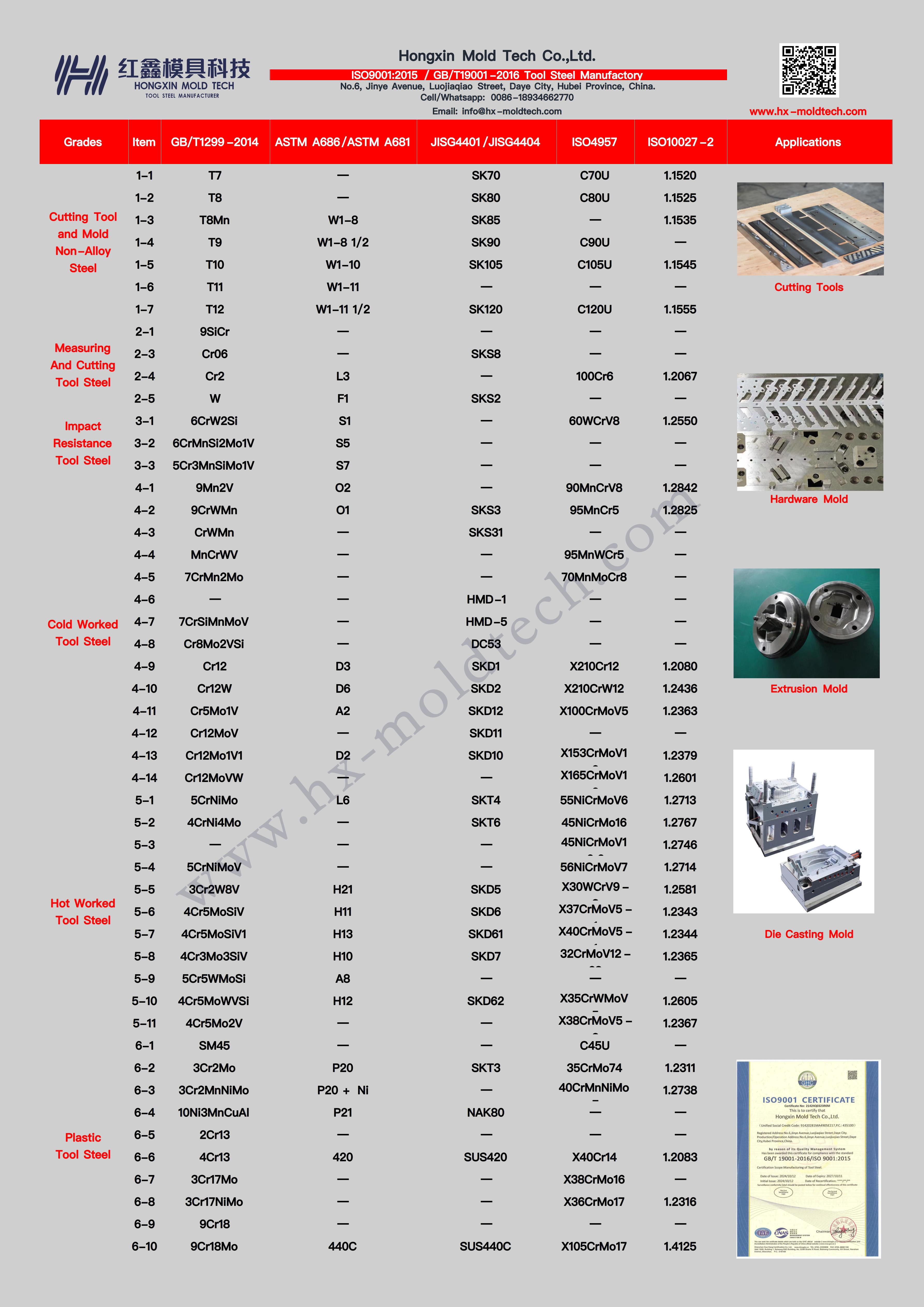

3: JIS SKD11 Steel equivalent

Country | China | Japan | Germany | USA |

Standard | GB/T 1299 | JIS G4404 | EN ISO 4957 | ASTM A681 |

Grade | Cr12Mo1V1 | SKD11 | 1.2379 | D2 |

4: JIS SKD11 steel chemical composition

Grade | C | Si | Mn | P | S | Cr | Mo | V |

Cr12Mo1V1 | 1.4-1.6 | ≤0.60 | ≤0.60 | 0.03 | 0.03 | 11-13 | 0.7-1.2 | ≤1.10 |

SKD11 | 1.4-1.6 | 0.4 | 0.6 | 0.03 | 0.03 | 11-13 | 0.8-1.2 | 0.2-0.5 |

1.2379 | 1.45-1.6 | 0.15-0.6 | 0.2-0.6 | 0.03 | 0.03 | 11-13 | 0.7-1.0 | 0.7-1.0 |

D2 | 1.4-1.6 | 0.1-0.6 | 0.1-0.6 | 0.03 | 0.03 | 11-13 | 0.7-1.2 | 0.5-1.1 |

5: JIS SKD11 steel mechanical properties

The mechanical properties mainly include tensile strength, yield strength, elongation, area or reduction, hardness, impact value, non-metalic inclusion etc. Different heat treatment, the mechanical properties will be different, such as normalized, tempered, QT. If you want to know the properties, kindly contact the salesman.

6: JIS SKD11 steel overviews

| Size | Round | Dia 6-1000mm | |

| Plate/Flat/Block | Thickness 8mm-300mm | ||

| Width 210mm-710mm | |||

| Process | EAF+LF+VD+Forged+Heat treatment(optional) | ||

| Heat teatment | Normalized ; Annealed ; Quenched ; Tempered | ||

| Surface condition | Black; Peeled; Polished; Machined; Grinded; Turned; Milled | ||

| Delivery condition | Forged; Hot rolled; Cold drawn | ||

| Test | Tensile strength, Yield strength, elongation, area of reduction, impact value, hardness, grain size, ultrasonic test, US inspection, magnetic particle testing, etc. | ||

| Payment terms | T/T;L/C;/Money gram/ Paypal | ||

| Trade terms | FOB; CIF; C&F; etc.. | ||

| Packing | Standard Packages, or as Customers Request | ||

| Delivery time | 30-45 days | ||

7: JIS SKD11 steel heating treatment

JIS SKD11steels alloy should be preheated very slowly to 815℃ (1500°F) and then temperature can be increased to 1010oC (1850°F). They are then held at 1010oC (1850°F) for 20 to 45 minutes and air cooled (air quenched).

Annealing

Annealing of JIS SKD11 tool steels material should be done at 871 to 898°C (1600 to 1650°F) followed by slow furnace cooling at 4.4°C (40°F) per hour or less.after which cooling rate may be increased. Suitable precautions must be taken to prevent excessive carburization or decarburization.

Stress Relieving

When desirable to relieve the strains of machining, heat JIS SKD11 grade steel slowly to 1050°-1250°F, allow to equalize, and then cool in still air (Strain Relieving).

Preheat Prior To Hardening

Preheat slowly to 1350°-1450°F and hold at this temperature until grade steel JIS SKD11 material is uniformly heated.

Hardening

After thorough preheating, heat to 1800°-1850°F. Hold the work piece at the hardening temperature until it is completely and uniformly heated.

Quenching

JIS SKD11 steel tool material is an air hardening steel and will develop hardness on cooling in still air. To avoid scaling and prevent decarburization of the work piece surface, controlled atmosphere or vacuum furnaces are recommended. If these furnaces are not available, pack hardening, salt baths or wrapping the piece in stainless steel foil will provide some degree of surface protection in the hardening process. Parts should be allowed to cool to 150F, or to where they can be held in the bare hand, and then temper immediately.

Tempering

The tempering temperature on material JIS SKD11 steel may be varied according to the desired hardness. JIS SKD11 steels can be tempered at 204°C (400°F) for achieving Rockwell C hardness of 61 and at 537°C (1000°F) for a Rockwell C hardness of 54.

8: Delivery condition

For hot forged or hot rolled bar, usually the delivery condition is hot forged or rolled, annealed, rough turned.

For hot forged plate, usually the delivery condition is hot forged, annealed, milled surface.

For hot rolled plate, usually the delivery condition is hot rolled, annealed, black surface.

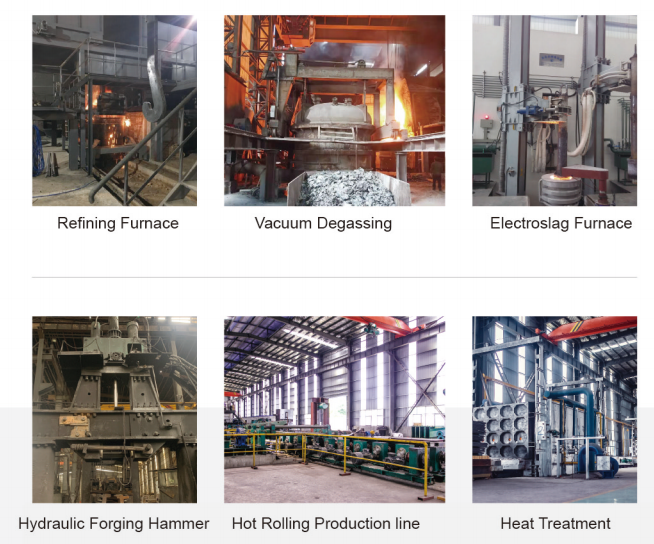

Hongxin Mold Tech Co.,Ltd. owns 1 set of Hot Rolling Production Line at size range flats 8-80*210-710mm, rounds 16-50mm Dia.

12 sets of Hydraulic Forging Hammers from Power 560kgs to 6000kgs which could cover flats 40-300*210-710mm.

8 sets of EF+LF+VD

5 sets of ESR

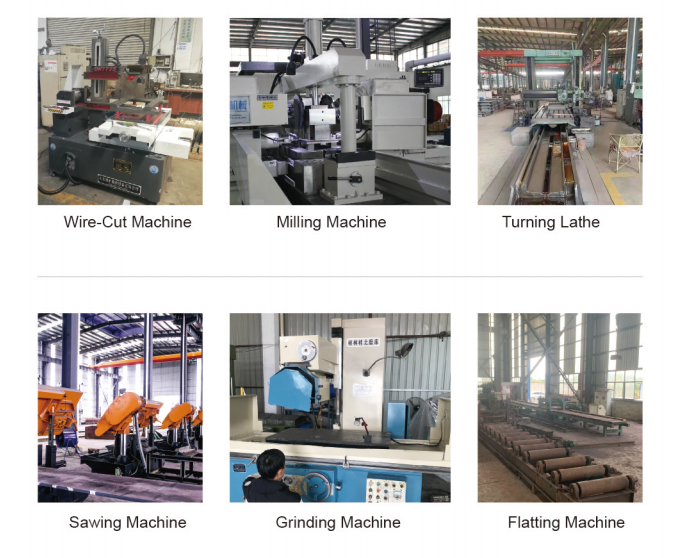

9 sets of Milling Machines

10 sets of Turning Lathes

6 sets of Precision Milling Machines.

CERTIFICATION: GB/T19001-2016/ISO9001:2015

Products' List

Packaging&Shipping

![]() Standard JSA JIS G 4404-2022 Alloy Tool Steels.pdf

Standard JSA JIS G 4404-2022 Alloy Tool Steels.pdf

Q1:Are you trading company or manufacturer ?

We are the largest tool steel manufacturer in Daye & Huangshi. we can provide a wide range of steel products.

Q2:What is alloy steel round bar export packing?

Usually bundling for large diameter,small diameter bars in bulk or as customer's demand.

Q3.What is your MOQ?

We accept small order,if it is stock,any quantities can be accepted.

Q4.What is your lead time?

Depends actual order,around 20-35 days,or negotiation.

Q5.Can you supply sample?

Yes,we can.Sample fee according to your size.

Q6:What certificates do you have?

ISO, ABS, BV, CCS, Dnv, Lr, Gl, Mill Certificate

Q7: How can I get your quotation as soon as possible?

The email will be checked within 24 hours,meanwhile,the Skype,Wechat and WhatsApp will be online in 24 hours.Please send us your requirement,we will work out a best price soon.