Daye Hongxin Mold Technology Co., Ltd. is an ISO certified manufacturer of tool steel, mold steel, alloy steel and precision machining of mechanical components with a total investment of 800 million RMB and covers an area of 150 acres. There are more than 500 employees, including more than 230 senior titles and technical professionals.

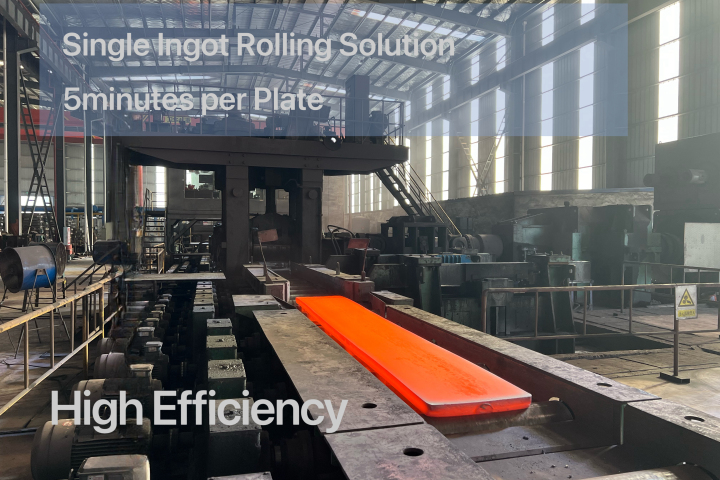

The company adopts high-end technology and uses energy-saving, environmentally and efficient CNC machineries and equipments (ferrous metal high alloy ingots casting, vacuum degassing, furnace refining, hydraulic forging hammers, 850mm hot rolling lines, heat treatment equipments and various specifications and models of CNC machine tools , CNC machining center, precision grinder, fast/slow wire machine, drilling machine, etc.). After the entire line is put into production, the company will have an optimized production process: a high-alloy product production chain from raw materials - smelting - refining - forging - rolling - heat treatment - milling and grinding - finishing - physical and chemical inspection of finished molds. The products are widely used in : Various high-end electronic equipments, auto parts, industrial and agricultural machinery equipment accessories, models and rollers, etc.

At present, the company is a nationally recognized high-tech enterprise, owns a high-tech R&D team, and has obtained a number of national patents. After the entire line put into operation, it is expected to produce more than one million pieces of high-end equipments and electronic parts annually, and hundreds of thusands of high-alloy rolling shaft parts, wear-resistant parts, temperature-resistant parts and special-shaped parts for industrial and agricultural machineries and equipments. There are more than tens of thousands of tons of ferrous metal smelting and casting ingots, the annual output value exceeds more than 800 million RMB, and the annual tax exceeds 80 million RMB. The company has now established a strong sales network and a complete customer service system, and the products are sold to more than 20 countries. It has multiple branches and a foreign trade company. Each branch is equipped with a full set of finishing equipment and can customize products according to customers’ requirements. In order to increase market, it plans to invest more than 100 million yuan in the next few years to import a set of high-end technical equipment "3D printing cast metal parts" production line, earns the company a leading position in the industry.

In the continuous advancement of our business, we have also found more comprehensive needs of global customers. Since 2024,we decided to export aboard directly, accepting customizable production to provide a better service relating tool steel products. With this, we have made a huge effort, this allows us to respond to our clients’ needs in the format they require with a high degree of flexibility and speed.