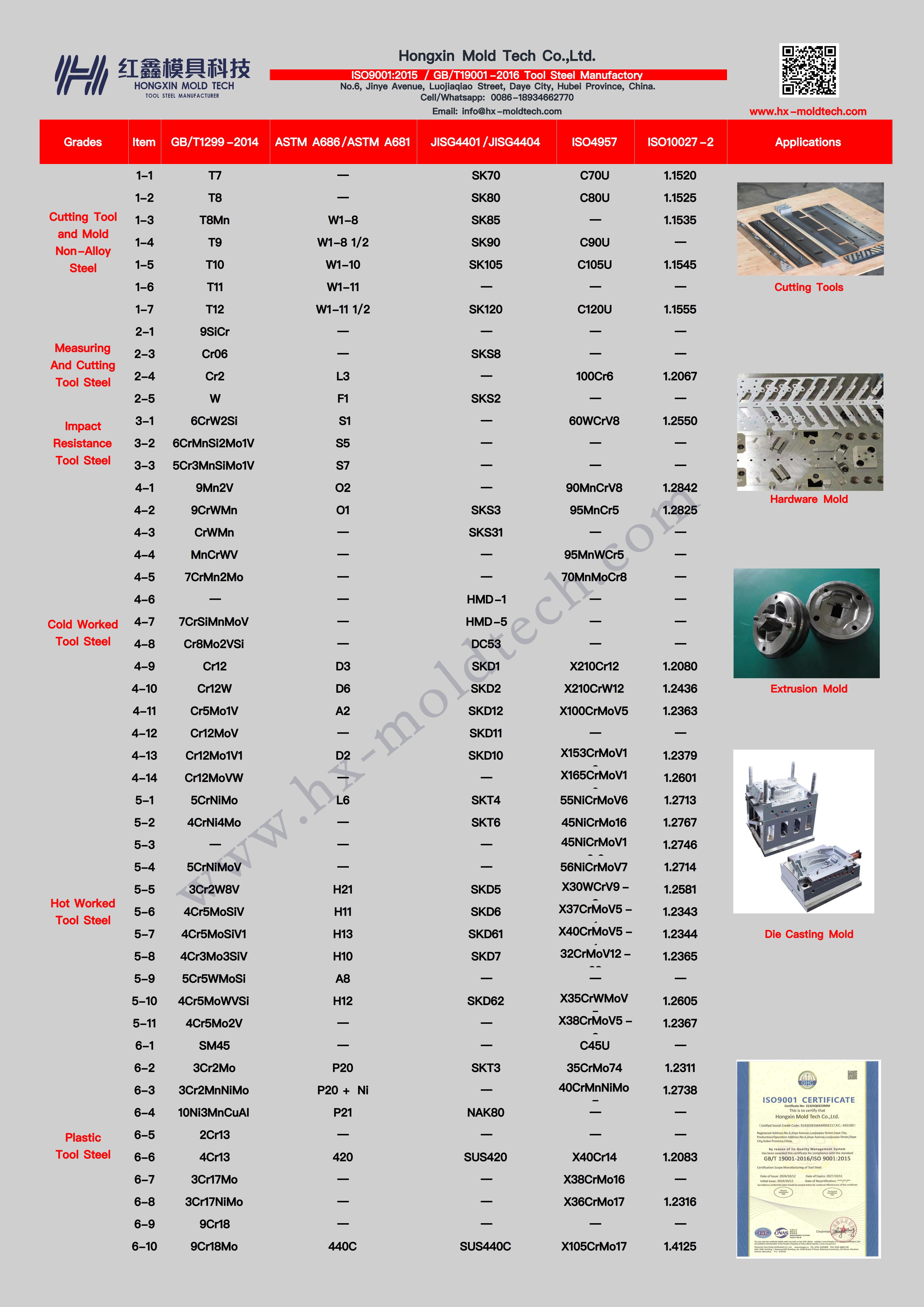

GB/T Cr12W Cold Worked Tool Steel

GB/T Cr12W is a high-carbon, high-chromium tool steel that is commonly used in the manufacturing of cutting and shaping tools, such as knives, punches, and dies. It offers excellent wear resistance, good toughness, and high hardness, making it suitable for applications where high levels of wear and abrasion are expected. DIN 1.2436 is often used in the production of cold work tools, such as cold heading dies, blanking dies, and cutting tools for sheet metal. It can also be used in applications where high precision and dimensional stability are required.

- HONGXIN

- DAYE

- 30 DAYS

- 8000 TON/MONTH

- Information

GB/T Cr12W Cold Worked Tool Steel

| 1: GB/T Cr12W steel introduction GB/T Cr12W tool steel is a high-carbon, 12% chromium alloy cold work tool steel with tungsten. GB/T Cr12W steel is an air hardening alloy tool steel with excellent resistance to wear and abrasion. As a high carbon high chromium tool steel GB/T Cr12W has better through hardening properties than D3 steel and dimensional stability combined with high resistance to tempering. 2: GB/T Cr12W Steel equivalent

|

3: GB/T Cr12W steel chemical composition

| Grade | C | Mn | P | S | Si | Cr | W | |||||

| D6 | 2.00 | 2.20 | 0.20 | 0.40 | 0.03 | 0.03 | 0.20 | 0.40 | 11.50 | 12.50 | 0.60 | 0.90 |

| 1.2436 / X210CrW12 | 2.00 | 2.30 | 0.30 | 0.60 | 0.03 | 0.03 | 0.10 | 0.40 | 11.00 | 13.00 | 0.60 | 0.80 |

| SKD2 | 2.00 | 2.30 | 0.30 | 0.60 | 0.03 | 0.03 | 0.10 | 0.60 | 11.00 | 13.00 | 0.60 | 0.80 |

4: GB/T Cr12W steel mechanical properties

The mechanical properties mainly include tensile strength, yield strength, elongation, area or reduction, hardness, impact value, non-metalic inclusion etc. Different heat treatment, the mechanical properties will be different, such as normalized, tempered, QT. If you want to know the properties, kindly contact the salesman.

5: GB/T Cr12W steel overviews

| Size | Round | Dia 12-500mm | |

| Plate/Flat/Block | Thickness 8mm~300mm | ||

| Width 210mm-710mm | |||

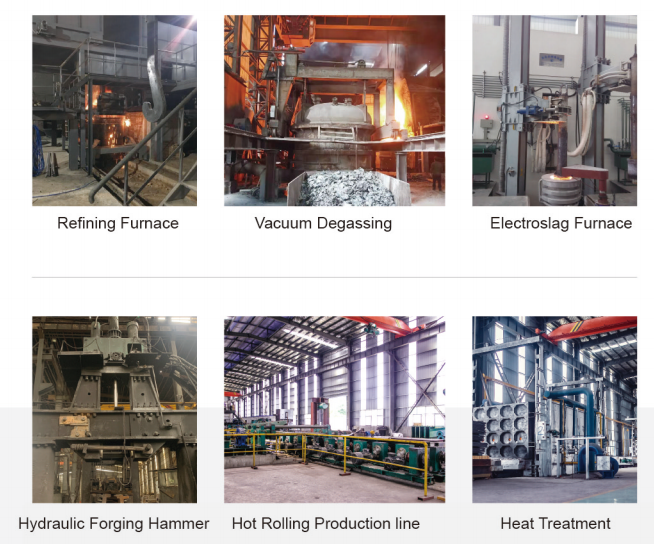

| Process | EAF+LF+VD+Forged+Heat treatment(optional) | ||

| Heat treatment | Normalized ; Annealed ; Quenched ; Tempered | ||

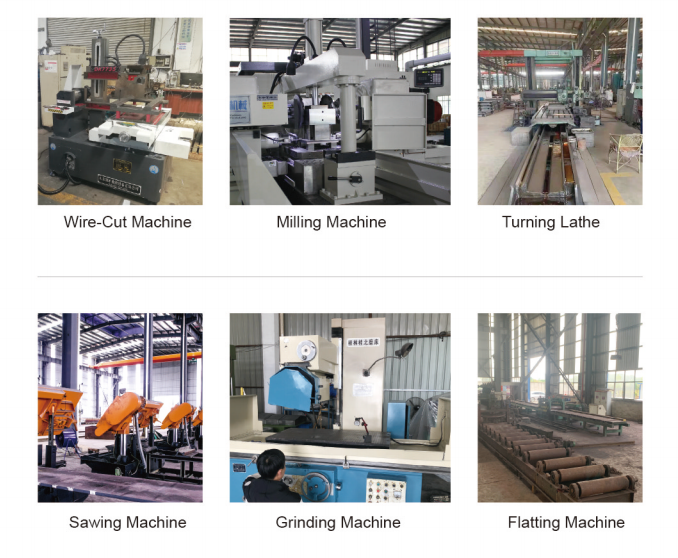

| Surface condition | Black; Peeled; Polished; Machined; Grinded; Turned; Milled | ||

| Delivery condition | Forged; Hot rolled; Cold drawn | ||

| Test | Tensile strength, Yield strength, elongation, area of reduction, impact value, hardness, grain size, ultrasonic test, US inspection, magnetic particle testing, etc. | ||

| Payment terms | T/T;L/C;/Money gram/ Paypal | ||

| Trade terms | FOB; CIF; C&F; etc.. | ||

| Packing | Standard Packages, or as Customers Request | ||

| Delivery time | 30-45 days | ||

6: Heat Treatment

Forging

Heat slowly to 700°C and then more rapidly to 900-1050°C. After forging cool slowly, preferably in a furnace.

Annealing

As this grade is supplied in the annealed and machineable condition re-annealing will only be necessary if it has been forged or hardened. Anneal the steel at 800-840°C and slow furnace cool. Hardness after annealing will be approximately 225HB.

Stress Relieving

When machining operations have been heavy or if the tool has an unbalanced section, remove stresses before hardening by heating up to 650-700°C, equalise, cool slowly.

Hardening

Pre heat slowly to 750-800°C and soak thoroughly. Continue heating up to the final hardening temperature of 950-980°C, allow the component to be heated through. Cool in air or quench in oil. X210CrW12 is suitable for vacuum (high speed gas) hardening.

Tempering

Heat the steel uniformly and thoroughly at the selected tempering temperature and hold for at least one hour per 25mm of total thickness. Double tempering of X210CrW12 should be carried out with intermediate cooling to room temperature.

| Temperature [℃] | 100 | 200 | 300 | 400 | 500 | 600 |

| Hardness [HRC] | 63 | 62 | 60 | 58 | 56 | 48 |

Heat Treatment

Heat treatment temperatures, rate of heating, cooling and soaking times will vary due to factors such as the shape and size of each component. Other considerations during the heat treatment process include the type of furnace, the quenching medium and work piece transfer facilities. Please consult a heat treatment specialist for full guidance on heat treatment.

7: Delivery condition

For hot forged or hot rolled bar, usually the delivery condition is hot forged or rolled, annealed, rough turned.

For hot forged plate, usually the delivery condition is hot forged, annealed, milled surface.

For hot rolled plate, usually the delivery condition is hot rolled, annealed, black surface.

Hongxin Mold Tech Co., Ltd. has the capacity to roll and forge round steel, steel flat, square steel, module, shaft and roller, etc. The main specifications of the products include 12-50mm rolling bars, 8~80x310~710mm rolling flats, 50~500mm forging round bars, and 80~300x210~710 mm forged flats and which the maximum piece weight can reach 50T.

CERTIFICATION: GB/T19001-2016/ISO9001:2015

Products' List

Q1:Are you trading company or manufacturer ?

We are the biggest tool steel factory at Daye &Huangshi. We can provide a wide range of steel products.

Q2:What is alloy steel round bar export packing?

Usually bundling for large diameter,small diameter bars in bulk or as customer's demand.

Q3.What is your MOQ?

We accept small order,if it is stock,any quantities can be accepted.

Q4.What is your lead time?

Depends actual order,around 20-35 days,or negotiation.

Q5.Can you supply sample?

Yes,we can.Sample fee according to your size.

Q6:What certificates do you have?

ISO, ABS, BV, CCS, Dnv, Lr, Gl, Mill Certificate

Q7: How can I get your quotation as soon as possible?

The email and fax will be checked within 24 hours,meanwhile,the Skype,Wechat and WhatsApp will be online in 24 hours.Please send us your requirement,we will work out a best price soon.