GB/T 4Cr4MoWVSi Hot Worked Mold Steel

4Cr4MoWVSi is a versatile alloy steel valued for its wear resistance, toughness, high-temperature stability, and resistance to thermal fatigue. It is widely used in the production of cutting tools, forging dies, molds, and other high-performance industrial components where durability and performance are critical.

- HONGXIN

- DAYE

- 30 DAYS

- 8000T/MONTH

- Information

1:GB/T 4Cr4MoWVSi steel introduction

1. High Wear Resistance

Applications: The addition of tungsten (W) and vanadium (V) enhances the wear resistance of 4Cr4MoWVSi, making it suitable for manufacturing tools and components that operate under abrasive conditions. Typical applications include cutting tools, molds, and dies that experience significant wear during use.

2. Good Toughness and Impact Resistance

Applications: Despite its hardness, 4Cr4MoWVSi maintains good toughness, which is essential for tools and components that must endure mechanical shock and impact without fracturing. This makes it ideal for forging dies, hammers, and other high-impact applications.

3. High-Temperature Stability

Applications: The presence of chromium, molybdenum, and tungsten contributes to the steel's ability to retain its hardness at elevated temperatures. This property is particularly valuable in hot-working tools, such as extrusion dies and forging tools, where the material must withstand high temperatures without losing its performance.

4. Resistance to Thermal Fatigue

Applications: 4Cr4MoWVSi steel is resistant to thermal fatigue, meaning it can endure repeated heating and cooling cycles without cracking or deforming. This makes it suitable for applications like hot forging dies and molds used in processes where temperature fluctuations are common.

5. Enhanced Hardness and Strength

Applications: The combination of molybdenum and tungsten contributes to the steel's overall hardness and strength, making it ideal for cutting and forming tools that require both sharpness and durability. Applications include high-performance cutting tools, cold work dies, and other precision tools.

6. Corrosion and Oxidation Resistance

Applications: Chromium provides a degree of corrosion and oxidation resistance, which is beneficial in environments where the steel is exposed to corrosive elements or high temperatures. This property makes 4Cr4MoWVSi useful in applications like chemical processing equipment and components exposed to harsh environments.

7. Tool Life Extension

Applications: The combination of high wear resistance, toughness, and thermal stability extends the service life of tools made from 4Cr4MoWVSi. This results in less frequent tool replacements and reduced downtime in industrial processes, improving overall efficiency.

8. Precision Machining

Applications: The steel's properties make it well-suited for precision machining, allowing for the production of high-quality, durable components. It is used in industries where precision and reliability are critical, such as aerospace, automotive, and heavy machinery.

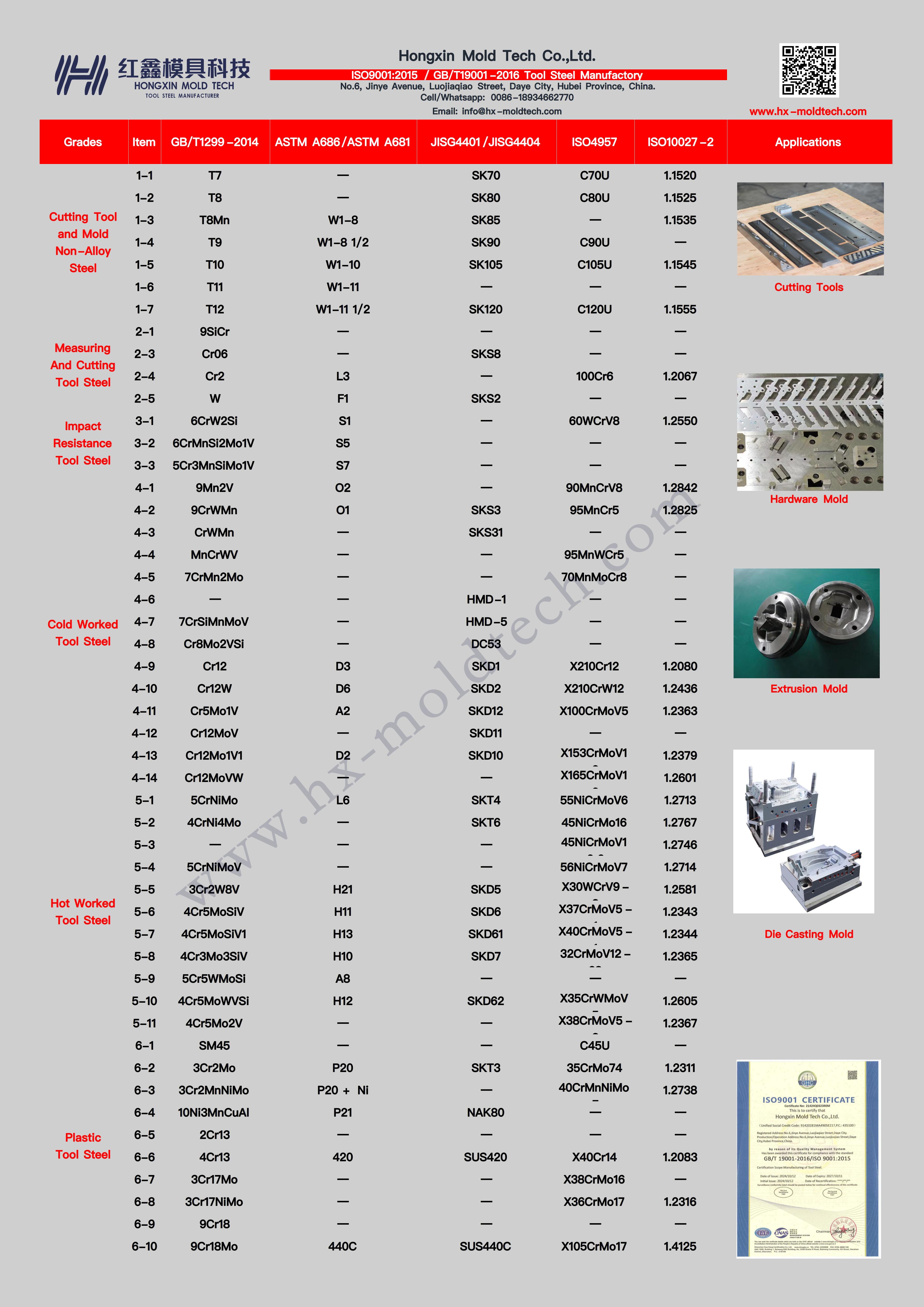

2: GB/T 4Cr4MoWVSi steel equivalent

| Country | China | Japan | Germany | USA |

| Standard | GB/T 1299 | JIS G4404 | DIN EN ISO4957 | ASTM A681 |

| Grade | 4Cr4MoWVS | SKD61 | 1.2344/X40CrMoV5-1 | H13 |

3: GB/T 4Cr4MoWVSi steel chemical composition

| Grade | C | Mn | P | S | Si | Cr | V | Mo | W | |||||||

| 4Cr4MoWVSi | 0.40 | 0.45 | 0.20 | 0.50 | ≤0.03 | ≤0.03 | 0.80 | 1.20 | 3.80 | 4.20 | 0.25 | 0.35 | 0.80 | 1.20 | 0.80 | 1.20 |

4: GB/T 4Cr4MoWVSi Steel Mechanical Properties

1. Hardness

As-quenched: Typically around 50-55 HRC.

After tempering: Can range from 48-53 HRC, depending on the tempering temperature. The steel maintains good hardness after tempering, which is essential for cutting tools and dies that need to retain sharpness and durability.

2. Tensile Strength

Ultimate Tensile Strength (UTS): Generally in the range of 1,500 - 2,000 MPa. This high tensile strength makes it suitable for components subjected to high mechanical stress.

3. Yield Strength

Yield Strength (YS): Typically around 1,200 - 1,600 MPa. High yield strength ensures that the material can withstand significant stress before deforming, which is crucial for tooling applications.

4. Toughness

Impact Toughness: 4Cr4MoWVSi has good toughness, allowing it to absorb impact without fracturing. This is particularly important for the steel's use in high-impact applications like forging dies and hammers.

5. Thermal Fatigue Resistance

Performance: The steel exhibits excellent resistance to thermal fatigue, making it suitable for applications involving repeated heating and cooling cycles, such as in hot forging or die-casting processes.

6. Wear Resistance

Performance: The combination of chromium, molybdenum, tungsten, and vanadium in the alloy gives it superior wear resistance, which is critical for tools and dies that are subjected to abrasive conditions.

7. High-Temperature Stability

Performance: 4Cr4MoWVSi retains its mechanical properties well at elevated temperatures, making it ideal for hot-working tools where maintaining hardness and strength at high temperatures is essential.

These mechanical properties make 4Cr4MoWVSi a highly durable and reliable steel for demanding industrial applications, particularly where high hardness, toughness, and resistance to wear and thermal fatigue are required.

5: GB/T 4Cr4MoWVSi Steel Overviews

| Size | Round | Dia 12-500mm | |

| Plate/Flat/Block | Thickness 8mm-300mm | ||

| Width 210mm-710mm | |||

| Process | EAF+LF+VD+Forged+Heat treatment(optional) | ||

| Heat treatment | Normalized ; Annealed ; Quenched ; Tempered | ||

| Surface condition | Black; Peeled; Polished; Machined; Grinded; Turned; Milled | ||

| Delivery condition | Forged; Hot rolled; Cold drawn | ||

| Test | Tensile strength, Yield strength, elongation, area of reduction, impact value, hardness, grain size, ultrasonic test, US inspection, magnetic particle testing, etc. | ||

| Payment terms | T/T;L/C;/Money gram/ Paypal | ||

| Trade terms | FOB; CIF; C&F; etc.. | ||

| Delivery time | 30-45 days | ||

| Packing | Standard Packages, or as Customers Request | ||

| Application | ASTM H10 tool steel are suitable for highly stressed hot work tools, mainly for the processing of heavy alloys, such as: Extrusion Industry: Dies, Inner Liners, Stems, Pressure Pads, Mandrels for Extrusion, Forging Industry: Forming Dies, Press Dies, Pressing Mandrels, Die Casting Industry: dies for die-casting, die inserts, hot shear blades, moulds for processing brass and light metal | ||

6.Heat Treatment

1. Annealing

Purpose: To soften the steel, relieve internal stresses, and improve machinability.

Process:

Heat the steel to a temperature of approximately 820-860°C.

Hold at this temperature for a sufficient period to allow the entire material to reach a uniform temperature.

Slowly cool in a furnace at a rate of 10-20°C per hour down to around 600°C.

Then, air cool to room temperature.

2. Hardening (Quenching)

Purpose: To increase hardness and strength by forming martensite.

Process:

Heat the steel to a temperature of approximately 1030-1080°C (depending on the specific application).

Hold at this temperature until the steel is uniformly heated.

Quench in oil or air (oil quenching is more common for achieving higher hardness).

Rapid cooling transforms the microstructure into martensite, increasing the steel's hardness.

3. Tempering

Purpose: To reduce brittleness after hardening and achieve the desired combination of hardness and toughness.

Process:

After quenching, temper the steel at a temperature typically ranging from 500-650°C.

Hold at the tempering temperature for 1-2 hours (depending on the section size and desired mechanical properties).

Air cool to room temperature.

Note: The exact tempering temperature and time depend on the desired hardness. Higher tempering temperatures result in lower hardness but increased toughness.

4. Stress Relieving (Optional)

Purpose: To relieve residual stresses after machining or other operations.

Process:

Heat the steel to a temperature of around 500-650°C.

Hold at this temperature for 1-2 hours.

Cool slowly in air.

5. Nitriding (Optional)

Purpose: To increase surface hardness and wear resistance without compromising the core toughness.

Process:

Heat the steel to 500-550°C in a nitrogen-rich atmosphere.

Hold for an extended period (depending on the desired case depth, typically 10-60 hours).

Cool slowly in air.

6. Cryogenic Treatment (Optional)

Purpose: To further refine the microstructure, increasing wear resistance and dimensional stability.

Process:

After quenching, cool the steel to sub-zero temperatures (usually -70°C to -196°C) for a few hours.

Follow with a tempering process.

Each step in this heat treatment process is carefully controlled to achieve the specific properties required for the application of 4Cr4MoWVSi steel. Adjustments in temperature, time, and cooling methods can be made to tailor the material properties to meet the needs of different industrial uses.

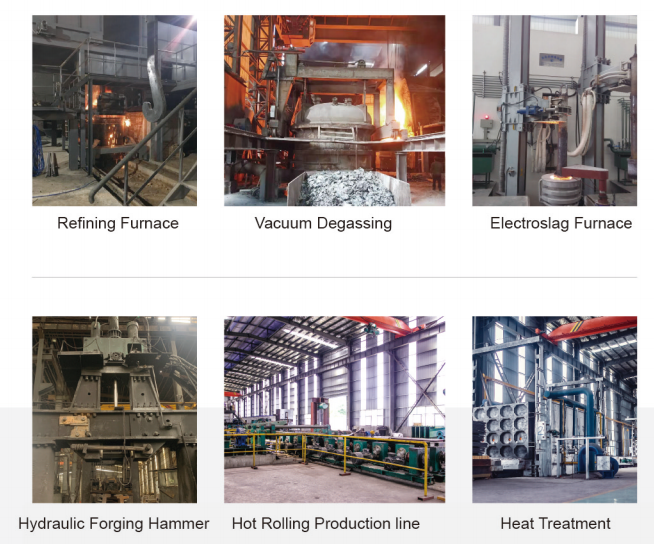

7: Delivery condition

For hot forged or hot rolled bar, usually the delivery condition is hot forged or rolled, annealed, rough turned.

For hot forged plate, usually the delivery condition is hot forged, annealed, milled surface.

For hot rolled plate, usually the delivery condition is hot rolled, annealed, black surface.

Hongxin Mold Tech Co.,Ltd. owns 1 set of Hot Rolling Production Line at size range flats 8-80*210-710mm, rounds 16-50mm Dia.

12 sets of Hydraulic Forging Hammers from Power 560kgs to 6000kgs which could cover flats 40-300*210-710mm.

8 sets of EF+LF+VD

5 sets of ESR

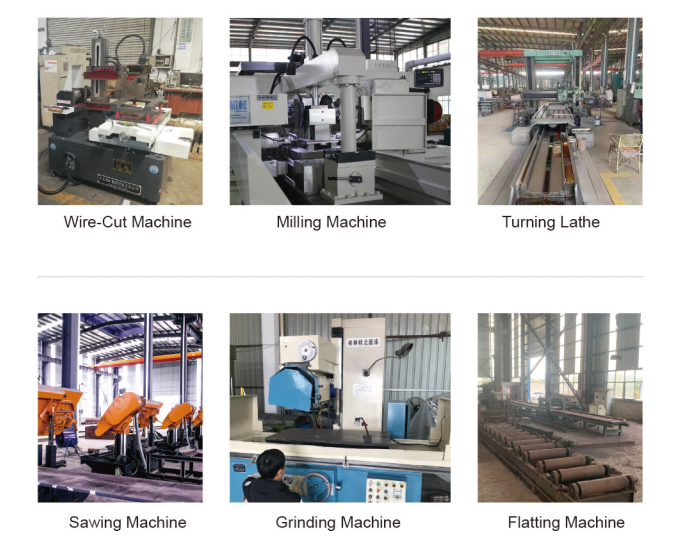

9 sets of Milling Machines

10 sets of Turning Lathes

6 sets of Precision Milling Machines.

CERTIFICATION: GB/T19001-2016/ISO9001:2015

Products' List

Q1:Are you trading company or manufacturer ?

We are the biggest tool steel factory at Daye & Huangshi. We can provide a wide range of steel products.

Q2:What is alloy steel round bar export packing?

Usually bundling for large diameter,small diameter bars in bulk or as customer's demand.

Q3.What is your MOQ?

We accept small order,if it is stock,any quantities can be accepted.

Q4.What is your lead time?

Depends actual order,around 20-35 days,or negotiation.

Q5.Can you supply sample?

Yes,we can.Sample fee according to your size.

Q6:What certificates do you have?

ISO, ABS, BV, CCS, Dnv, Lr, Gl, Mill Certificate

Q7: How can I get your quotation as soon as possible?

The email and fax will be checked within 24 hours,meanwhile,the Skype,Wechat and WhatsApp will be online in 24 hours.Please send us your requirement,we will work out a best price soon.

Any interests in our company and products, please feel free to contact us for quotation. We warmly welcome you to our factory.