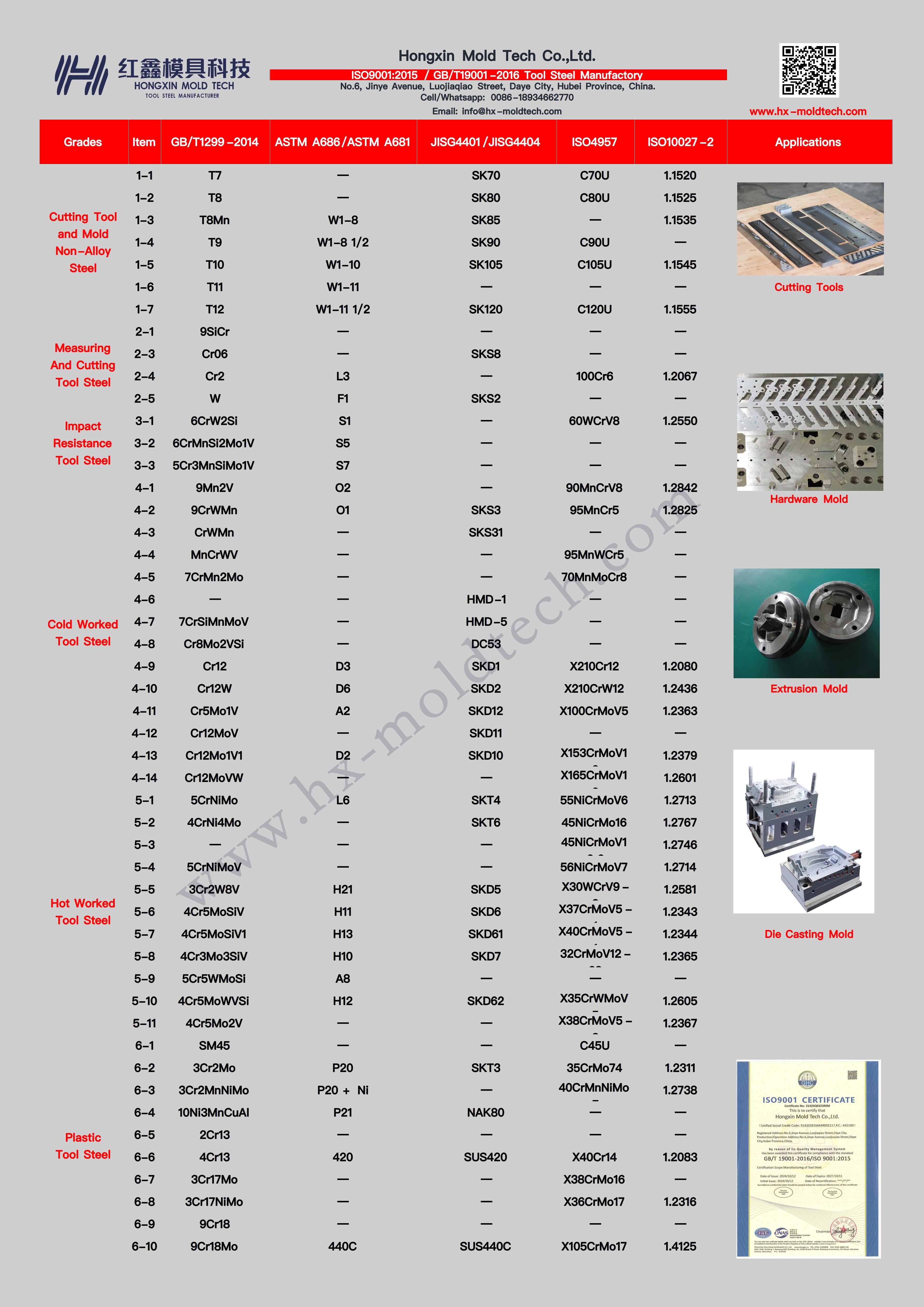

DIN 1.2343(X37CrMoV5-1)Hot Worked Mold Steel

DIN 1.2343 material is a versatile and reliable choice for a wide range of industrial applications, particularly in hot work and high-temperature environments. Its excellent properties make it a preferred material for tooling and components that require high performance and durability.Hot Work Tooling, Aluminum and Non-Ferrous Metal Processing,Plastic Molding,High-Pressure Die Casting and General Engineering Applications are all its application.

- HONGXIN

- DAYE

- 30 DAYS

- 8000 TON/MONTH

- Information

DIN 1.2343(X37CrMoV5-1) Hot Worked Mold Steel

1: DIN 1.2343(X37CrMoV5-1) introduction

DIN 1.2343(X37CrMoV5-1) tool steel is a 5% chromium hot work tool steel that is represented by its excellent impact toughness. Chromium hot-work tool steels are designated as group H steels according to the AISI classification system, and specified in ASTM A681standard. The most commonly used chromium hot-work steels are DIN 1.2343(X37CrMoV5-1) tool steel, H12 tool steel, and H13 steel, within the series from H1 to H19.

DIN 1.2343(X37CrMoV5-1) tool steel is a deep-hardening, air-hardening steel and DIN 1.2343(X37CrMoV5-1) alloy steel could be deep hardened by heat treatment and air-quenching. That gives minimal size change during heat treatment. DIN 1.2343(X37CrMoV5-1) hot work steel also has super resistance to thermal fatigue cracking and superb resistance to gross cracking and thermal shock when water cooled in service.

2: DIN 1.2343(X37CrMoV5-1) Steel equivalent

| Country | China | Japan | Germany | USA | UK |

| Standard | GB/T 1299 | JIS G4404 | DIN EN ISO4957 | ASTM A681 | BS 4659 |

| Grade | 4Cr5MoV | SKD6 | 1.2343/X37CrMoV5-1 | H11/T20811 | BH11 |

3: DIN 1.2343(X37CrMoV5-1) steel chemical composition

| Grade | C | Mn | P | S | Si | Cr | V | Mo | ||||||

| H11/T20811 | 0.35 | 0.45 | 0.20 | 0.60 | 0.03 | 0.03 | 0.80 | 1.25 | 4.75 | 5.50 | 0.30 | 0.60 | 1.10 | 1.60 |

| 1.2343/ X37CrMoV5-1 | 0.28 | 0.35 | 0.10 | 0.40 | … | … | 0.80 | 1.20 | 2.70 | 3.20 | 0.40 | 0.70 | 1.10 | 1.50 |

| SKD6 | 0.32 | 0.42 | … | 0.50 | 0.03 | 0.03 | 0.80 | 1.20 | 4.50 | 5.50 | 0.30 | 0.50 | 1.00 | 1.50 |

| BH11 | 0.32 | 0.40 | … | 0.40 | 0.35 | 0.35 | 0.85 | 1.15 | 4.75 | 5.25 | 0.30 | 0.50 | 1.25 | 1.75 |

4: DIN 1.2343(X37CrMoV5-1) steel mechanical properties

The mechanical properties mainly include tensile strength, yield strength, elongation, area or reduction, hardness, impact value, non-metalic inclusion etc. Different heat treatment, the mechanical properties will be different, such as normalized, tempered, QT. If you want to know the properties, kindly contact the salesman.

5: DIN 1.2343(X37CrMoV5-1) steel overviews

| Size | Round | Dia 12-500mm | |

| Plate/Flat/Block | Thickness 8mm-300mm | ||

| Width 210mm-710mm | |||

| Process | EAF+LF+VD+Forged+Heat treatment(optional) | ||

| Heat treatment | Normalized ; Annealed ; Quenched ; Tempered | ||

| Surface condition | Black; Peeled; Polished; Machined; Grinded; Turned; Milled | ||

| Delivery condition | Forged; Hot rolled; Cold drawn | ||

| Test | Tensile strength, Yield strength, elongation, area of reduction, impact value, hardness, grain size, ultrasonic test, US inspection, magnetic particle testing, etc. | ||

| Payment terms | T/T;L/C;/Money gram/ Paypal | ||

| Trade terms | FOB; CIF; C&F; etc.. | ||

| Packing | standard packages or as per customers request. | ||

| Delivery time | 30-45 days | ||

6: Heat treatment

Annealing

Slowly heat to 843 – 898(1550-1650 F) then slowly Cool to 538(1000) in heat treatment furnace. Then frosty in make public. After annealing hardness HBS: 235 Max

Hardening

DIN 1.2343(X37CrMoV5-1) steel having enormously high hardenability and should be hardened by cooling in yet appearance. The use of a salt bath or controlled mood furnace is desirable to minimize decarburization, and if not user-simple, pack hardening in spent arena coke is suggested. The temperature employed is usually 1800-1850F, depending upon size section.

Quenching

Quenching temperature / ℃ | salt bath furnace: 996

Quenching temperature / ℃ | controlled atmosphere furnace: 1010

The heat preservation time/min: 5 ~ 15

Quenching medium: air cooling .

Tempering

Tempering temperature / : 552

After tempering hardness HRC or future: 52

7: Delivery condition

For hot forged or hot rolled bar, usually the delivery condition is hot forged or rolled, annealed, rough turned.

For hot forged plate, usually the delivery condition is hot forged, annealed, milled surface.

For hot rolled plate, usually the delivery condition is hot rolled, annealed, black surface.

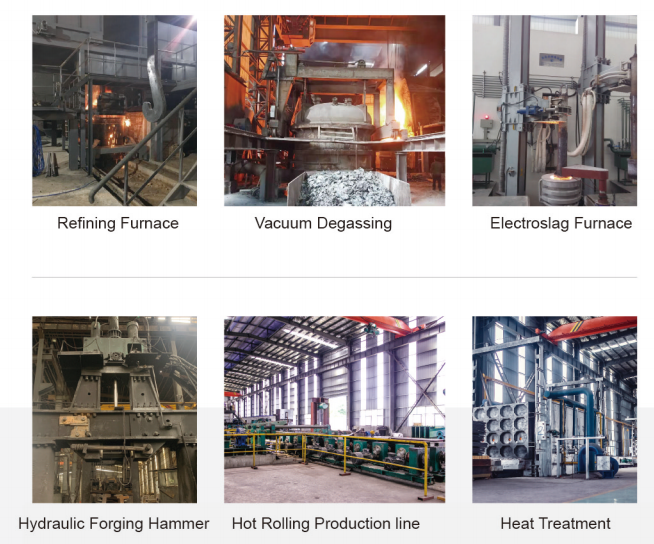

Hongxin Mold Tech Co.,Ltd. owns 1 set of Hot Rolling Production Line at size range flats 8-80*210-710mm, rounds 16-50mm Dia.

12 sets of Hydraulic Forging Hammers from Power 560kgs to 6000kgs which could cover flats 40-300*210-710mm.

8 sets of EF+LF+VD

5 sets of ESR

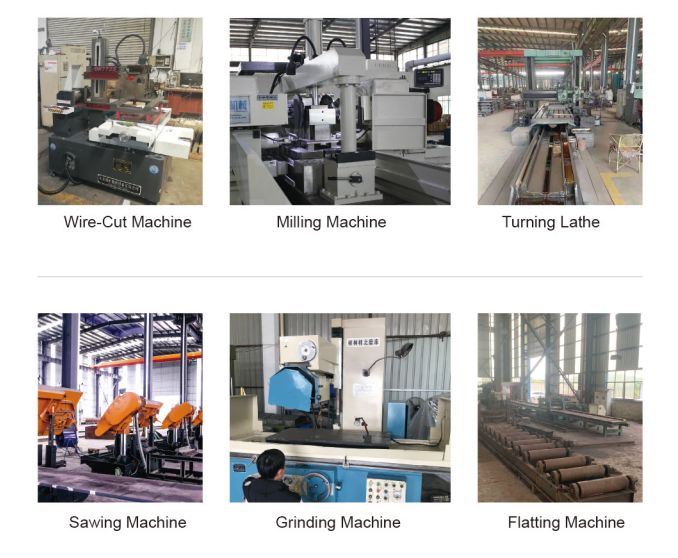

9 sets of Milling Machines

10 sets of Turning Lathes

6 sets of Precision Milling Machines.

CERTIFICATION: GB/T19001-2016/ISO9001:2015

Products' List

Q1:Are you trading company or manufacturer ?

We are the biggest tool steel factory at Daye & Huangshi. We can provide a wide range of steel products.

Q2:What is alloy steel round bar export packing?

Usually bundling for large diameter,small diameter bars in bulk or as customer's demand.

Q3.What is your MOQ?

We accept small order,if it is stock,any quantities can be accepted.

Q4.What is your lead time?

Depends actual order,around 20-35 days,or negotiation.

Q5.Can you supply sample?

Yes,we can.Sample fee according to your size.

Q6:What certificates do you have?

ISO, ABS, BV, CCS, Dnv, Lr, Gl, Mill Certificate

Q7: How can I get your quotation as soon as possible?

The email and fax will be checked within 24 hours,meanwhile,the Skype,Wechat and WhatsApp will be online in 24 hours.Please send us your requirement,we will work out a best price soon.