DIN 1.2826(60MnSiCr4)Cold Worked Mold Steel

1.2826 is a high-strength alloy tool steel, belonging to cold work die steel, known for its excellent wear resistance, good toughness and high hardenability. This steel is widely used in the manufacture of tools and molds that need to withstand high pressure and wear, such as stamping molds, cold extrusion molds, drawing molds, powder metallurgy molds and so on.

- HONGXIN

- 中国

- 30 DAYS

- 8000T/MONTH

- Information

1.DIN 1.2826 perform well, and the following are its main characteristics: - High hardness: 1.2826 has high hardness, which makes it suitable for making cutting tools and stamping dies. - Induction hardening properties: Due to the presence of certain carbon and chromium elements in its composition, 1.2826 can be used to improve surface hardness and wear resistance through the induction hardening process. - Heat resistance: The steel has excellent heat resistance and is able to maintain stable performance in high temperature environments.

2. DIN 1.2826 steel application

DIN 1.2826 is widely used in the manufacture of tools and molds that need to withstand high pressure and wear, such as stamping molds, cold extrusion molds, drawing molds, powder metallurgy molds and so on.

3. DIN 1.2826 steel chemical composition

| Grade | C | Si | Mn | P | S | Cr |

| 60MnSiCr4 | 0.58-0.65 | 0.8-1 | 0.8-1.2 | 0-0.03 | 0-0.03 | 0.2-0.4 |

4. DIN 1.2826 mechanical properties

High hardness: 1.2826 has high hardness and is suitable for making cutting tools and stamping dies. - Induction Hardening Properties: Due to the presence of certain carbon and chromium elements in its composition, 1.2826 can improve surface hardness and abrasion resistance through induction hardening process. - Heat Resistance: The steel has excellent heat resistance and is able to maintain stable performance in high temperature environments.

5: Delivery condition

For hot forged or hot rolled bar, usually the delivery condition is hot forged or rolled, annealed, rough turned.

For hot forged plate, usually the delivery condition is hot forged, annealed, milled surface.

For hot rolled plate, usually the delivery condition is hot rolled, annealed, black surface.

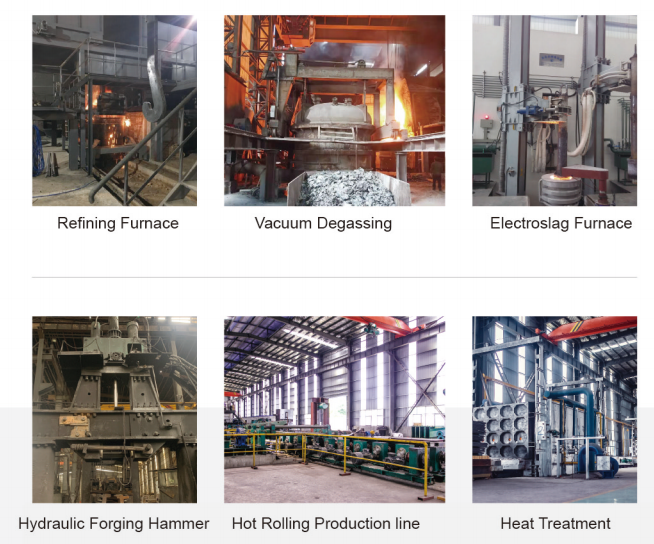

Hongxin Mold Tech Co.,Ltd. owns 1 set of Hot Rolling Production Line at size range flats 8-80*210-710mm, rounds 16-50mm Dia.

12 sets of Hydraulic Forging Hammers from Power 560kgs to 6000kgs which could cover flats 40-300*210-710mm.

8 sets of EF+LF+VD

5 sets of ESR

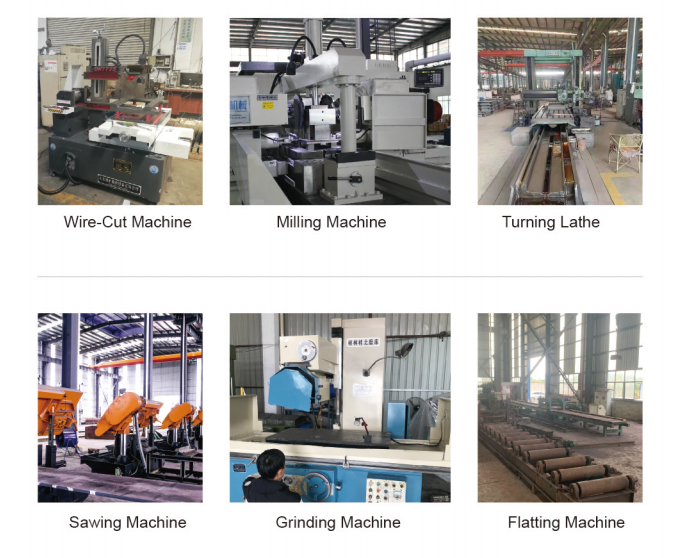

9 sets of Milling Machines

10 sets of Turning Lathes

6 sets of Precision Milling Machines.

CERTIFICATION: GB/T19001-2016/ISO9001:2015

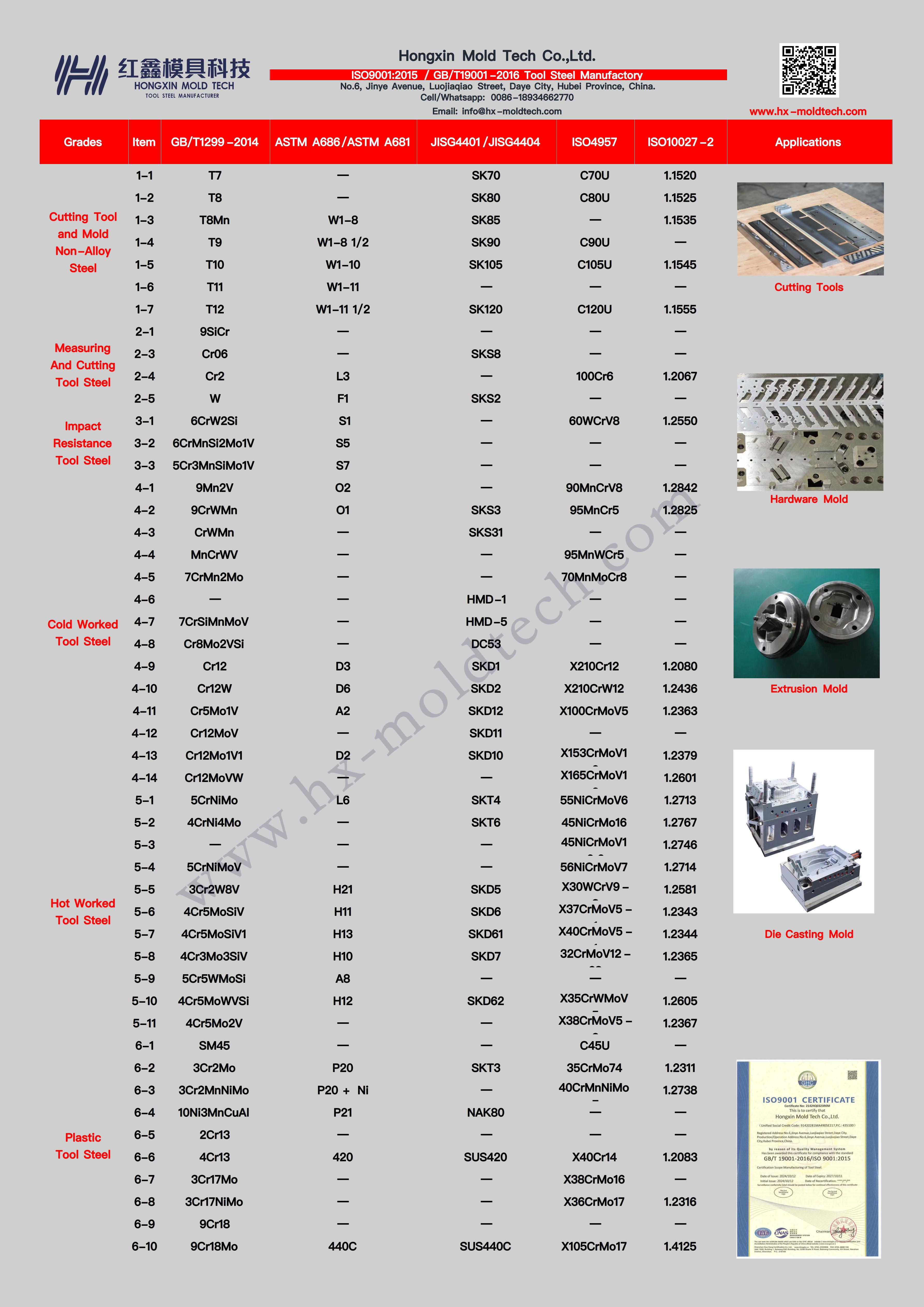

Products' List

Packaging&Shipping

Q1:Are you trading company or manufacturer ?

We are the largest tool steel manufacturer in Daye,Huangshi,Hubei,China. we can provide a wide range of steel products.

Q2:What is alloy steel round bar export packing?

Usually bundling for large diameter,small diameter bars in bulk or as customer's demand.

Q3.What is your MOQ?

We accept small order,if it is stock,any quantities can be accepted.

Q4.What is your lead time?

Depends actual order,around 20-35 days,or negotiation.

Q5.Can you supply sample?

Yes,we can.Sample fee according to your size.

Q6:What certificates do you have?

ISO, ABS, BV, CCS, Dnv, Lr, Gl, Mill Certificate

Q7: How can I get your quotation as soon as possible?

The email will be checked within 24 hours,meanwhile,the Skype,Wechat and WhatsApp will be online in 24 hours.Please send us your requirement,we will work out a best price soon.