DIN 1.2365 Hot Worked Mold Steel

1. High wear resistance: DIN 1.2365 is known for its excellent wear resistance, making it suitable for applications where tools are subjected to high levels of wear and abrasion.

2. Good toughness: The high toughness of DIN 1.2365 makes it suitable for applications where tools are subjected to high impact loads, such as forging and extrusion.

3. Good thermal conductivity: DIN 1.2365 has good thermal conductivity, allowing for efficient heat transfer during hot work processes, which helps in preventing overheating and prolonging tool life.

4. Easy machinability: DIN 1.2365 can be easily machined and shaped into various tooling components, making it a versatile material for manufacturing applications.

- HONGXIN

- DAYE

- 30 DAYS

- 8000T/MONTH

- Information

1:DIN 1.2365 steel introduction

DIN 1.2365 Tool Steel is one hot works tool steel in ASTM A681 standard, which is for alloy tool steel. The ASTM/AISI classifies chromium hot work tool steels as group H steels, ranging from H10, H11, h12 to H19. AISI H10 Tool Steel is one of chromium hot work tool steel that exhibits excellent resistance to softening at elevated temperature.

DIN 1.2365 Tool Steel is capable of being heat treated to higher hardness than the tungsten hot work steels, and in addition offers greater toughness. H10 tool steel has good thermal fatigue characteristics, and unlike the tungsten hot work steels and H10 hot work tool steels may be safely water cooled in service.

DIN 1.2365 hot work tool steel is recommended for difficult hot work tooling applications such as hot punches, die casting dies, forging dies, hot shear blades, hot gripper dies, and extrusion tooling etc.

2: DIN 1.2365 steel equivalent

| Country | China | Japan | Germany | USA | UK |

| Standard | GB/T 1299 | JIS G4404 | DIN EN ISO4957 | ASTM A681 | BS 4659 |

| Grade | 3Cr3Mo3V | SKD7 | 1.2365/32CrMoV12-28 | H10/T20810 | BH10 |

3:DIN 1.2365 steel chemical composition

| Grade | C | Mn | P | S | Si | Cr | V | Mo | ||||||

| H10/T20810 | 0.35 | 0.45 | 0.20 | 0.70 | ≤ | 0.03 | 0.80 | 1.25 | 3.00 | 3.75 | 0.25 | 0.75 | 2.00 | 3.00 |

| 1.2365/ 32CrMoV12-28 | 0.28 | 0.35 | 0.15 | 0.45 | ≤ | 0.03 | 0.10 | 0.40 | 2.70 | 3.20 | 0.40 | 0.70 | 2.50 | 3.00 |

| SKD7 | 0.28 | 0.35 | 0.15 | 0.45 | 0.03 | 0.03 | 0.10 | 0.40 | 2.70 | 3.20 | 0.40 | 0.70 | 2.50 | 3.00 |

| BH10 | 0.30 | 0.40 | ≤ | 0.40 | 0.35 | 0.35 | 0.75 | 1.10 | 2.80 | 3.20 | 0.30 | 0.50 | 2.65 | 2.95 |

4: DIN 1.2365 steel mechanical properties

The mechanical properties mainly include tensile strength, yield strength, elongation, area or reduction, hardness, impact value, non-metalic inclusion etc. Different heat treatment, the mechanical properties will be different, such as normalized, tempered, QT. If you want to know the properties, kindly contact the salesman.

5:DIN 1.2365 steel overviews

| Size | Round | Dia 12-500mm | |

| Plate/Flat/Block | Thickness 8mm-300mm | ||

| Width 210mm-710mm | |||

| Process | EAF+LF+VD+Forged+Heat treatment(optional) | ||

| Heat treatment | Normalized ; Annealed ; Quenched ; Tempered | ||

| Surface condition | Black; Peeled; Polished; Machined; Grinded; Turned; Milled | ||

| Delivery condition | Forged; Hot rolled; Cold drawn | ||

| Test | Tensile strength, Yield strength, elongation, area of reduction, impact value, hardness, grain size, ultrasonic test, US inspection, magnetic particle testing, etc. | ||

| Payment terms | T/T;L/C;/Money gram/ Paypal | ||

| Trade terms | FOB; CIF; C&F; etc.. | ||

| Delivery time | 30-45 days | ||

| Packing | Standard Packages, or as Customers Request | ||

| Application | ASTM H10 tool steel are suitable for highly stressed hot work tools, mainly for the processing of heavy alloys, such as: Extrusion Industry: Dies, Inner Liners, Stems, Pressure Pads, Mandrels for Extrusion, Forging Industry: Forming Dies, Press Dies, Pressing Mandrels, Die Casting Industry: dies for die-casting, die inserts, hot shear blades, moulds for processing brass and light metal | ||

6.Heat Treatment

Annealing

Heating slowly and uniformly to 750~790℃, furnace cooling to

600℃ at a rate 10~20℃/hr, further cooling in air. Hardness after annealing: max. 205 HB. Suitable precautions must be taken to prevent excessive carburization or decarburization.

Stress relieving

600 to 650°C (1112 to 1202°F) Slow cooling in furnace; intended to relieve stresses set up by extensive machining, or in complex shapes. After through heating, hold in neutral atmosphere for 1 -2 hours.

Hardening

DIN 1.2365 steel is a very deep hardening steel, and although oil quenching may be used where maximum hardness is required, air hardening is recommended for most applications. The use of salt bath or controlled atmosphere furnace is desirable to minimize decarburization, and if not available, pack hardening spent pitch temperature employed is usually in the range of 982°C -1037°C.

1010 to 1050°C (1850 to 1922°F) Oil, salt bath (500-550°C / 932-1022°F), Holding time after temperature equalization: 15 to 30 minutes. Obtainable hardness: 52 -56 HRC

Tempering

Slow heating to tempering temperature immediately after hardening / time in furnace 1 hour for each 20 mm of work piece thickness but at least 2 hours / cooling in air. It is recommended to temper at least twice. A third tempering cycle for the purpose of stress relieving may be advantageous 1st tempering approx. 30°C (86°F) above maximum secondary hardness. 2nd tempering to desired working hard-ness. The tempering chart shows average tem-pered hardness values. 3rd for stress relieving at a temperature 30 -50°C (86 to 122°F) below highest tempering temperature

7: Delivery condition

For hot forged or hot rolled bar, usually the delivery condition is hot forged or rolled, annealed, rough turned.

For hot forged plate, usually the delivery condition is hot forged, annealed, milled surface.

For hot rolled plate, usually the delivery condition is hot rolled, annealed, black surface.

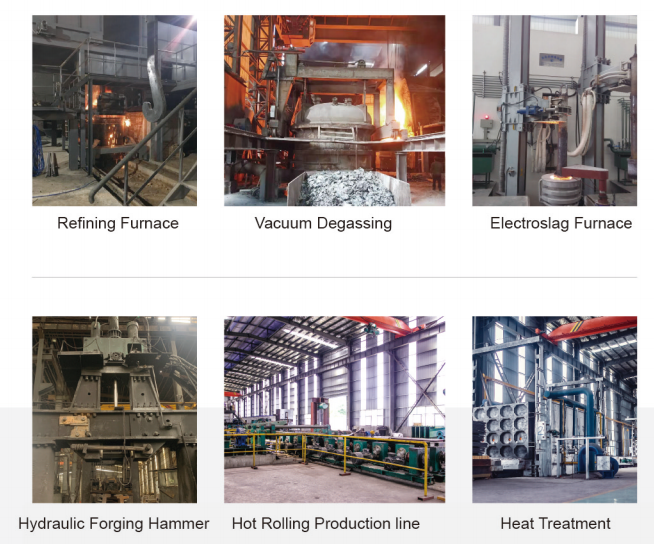

Hongxin Mold Tech Co.,Ltd. owns 1 set of Hot Rolling Production Line at size range flats 8-80*210-710mm, rounds 16-50mm Dia.

12 sets of Hydraulic Forging Hammers from Power 560kgs to 6000kgs which could cover flats 40-300*210-710mm.

8 sets of EF+LF+VD

5 sets of ESR

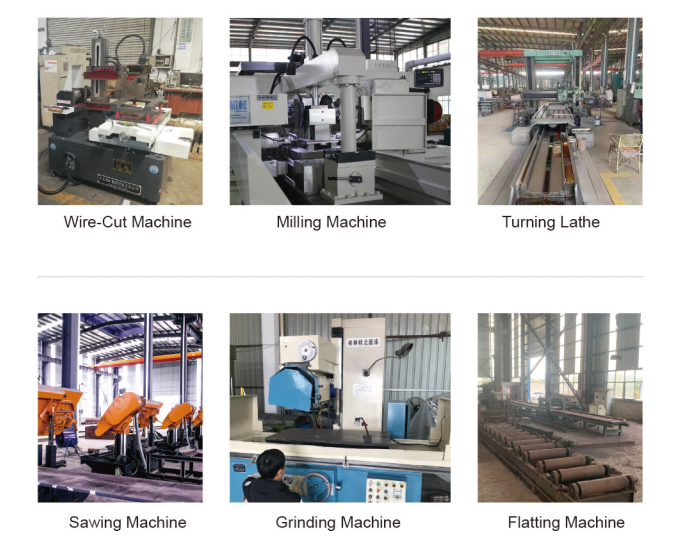

9 sets of Milling Machines

10 sets of Turning Lathes

6 sets of Precision Milling Machines.

CERTIFICATION: GB/T19001-2016/ISO9001:2015

Products' List

Q1:Are you trading company or manufacturer ?

We are the biggest tool steel factory at Daye & Huangshi. We can provide a wide range of steel products.

Q2:What is alloy steel round bar export packing?

Usually bundling for large diameter,small diameter bars in bulk or as customer's demand.

Q3.What is your MOQ?

We accept small order,if it is stock,any quantities can be accepted.

Q4.What is your lead time?

Depends actual order,around 20-35 days,or negotiation.

Q5.Can you supply sample?

Yes,we can.Sample fee according to your size.

Q6:What certificates do you have?

ISO, ABS, BV, CCS, Dnv, Lr, Gl, Mill Certificate

Q7: How can I get your quotation as soon as possible?

The email and fax will be checked within 24 hours,meanwhile,the Skype,Wechat and WhatsApp will be online in 24 hours.Please send us your requirement,we will work out a best price soon.

Any interests in our company and products, please feel free to contact us for quotation. We warmly welcome you to our factory.