DIN 1.1535 Free Cutting Steel

The usage of DIN 1.1535 is:cutting tools, knives, and other sharp-edged instruments.

- HONGXIN

- DAYE

- 30 DAYS

- 8000 TON/MONTH

- Information

DIN 1.1535 Free Cutting Steel

1: DIN 1.1535 steel introduction DIN 1.1535 is a Germany standard for a specific type of steel material. It is a high carbon, high chromium steel that is commonly used in the manufacturing of cutting tools, knives, and other sharp-edged instruments. This type of steel is known for its excellent wear resistance, hardness, and edge retention properties, making it a popular choice for applications where a sharp and durable cutting edge is required. 2: DIN 1.1535 steel chemical composition

|

3: DIN 1.1535 steel mechanical properties

T10 steel is the most common carbon tool steel in China, with moderate toughness and low production cost. After heat treatment, the hardness of the material can reach above 60 HRC. However, this steel has low hardenability and low heat resistance (250°C). It is not easy to overheat and still maintain fine grains. The toughness is acceptable, the strength and wear resistance are higher than T7 T8 and T9, but the hot hardness is low, the hardenability is still not high, and the quenching deformation is large.

T10 tool steel grade designation

T – Tool

10 – Average carbon content – 10‰ (1%)

A – Hi

4: DIN 1.1535 steel overviews

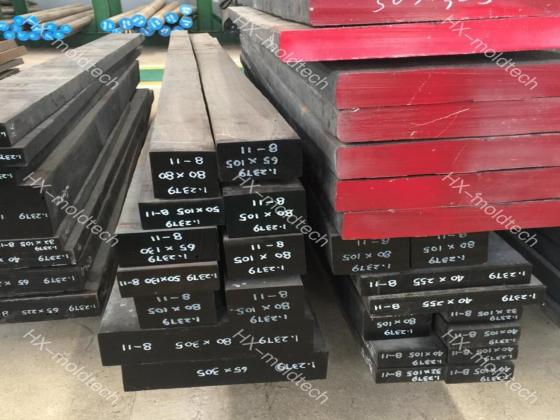

| Size | Round | Dia 12-500mm | |

| Plate/Flat/Block | Thickness 8mm~300mm | ||

| Width 210mm-710mm | |||

| Process | EAF+LF+VD+Forged+Heat treatment(optional) | ||

| Heat treatment | Normalized ; Annealed ; Quenched ; Tempered | ||

| Surface condition | Black; Peeled; Polished; Machined; Grinded; Turned; Milled | ||

| Delivery condition | Forged; Hot rolled; Cold drawn | ||

| Test | Tensile strength, Yield strength, elongation, area of reduction, impact value, hardness, grain size, ultrasonic test, US inspection, magnetic particle testing, etc. | ||

| Payment terms | T/T;L/C;/Money gram/ Paypal | ||

| Trade terms | FOB; CIF; C&F; etc.. | ||

| Packing | Standard Packages, or as Customers Request | ||

| Delivery time | 30-45 days | ||

5: Heat Treatment

Normalizing

Normalizing temperature 830~850°C. Air-cooled, hardness 255~321HBW.

Ordinary annealing

Annealing temperature 750 ~ 760°C. Keep warm for 2 ~ 4h, and then cool to 500 ~ 600°C at a cooling rate of <30’C/h, and air-cooled.

Isothermal spheroidizing annealing

1) 750~760°C×2~4h. 680~700°C×4~6h. The furnace is cooled again to 5m ~ 600°C, and it is air-cooled. Hardness≤207HBW.

2) 750~770°C ×1~2h, 680~700°C ×2 ~3h, hardness 163~207HBw, pearlite grade 1~5

For hot forged or hot rolled bar, usually the delivery condition is hot forged or rolled, annealed, rough turned.

For hot forged plate, usually the delivery condition is hot forged, annealed, milled surface.

For hot rolled plate, usually the delivery condition is hot rolled, annealed, black surface.

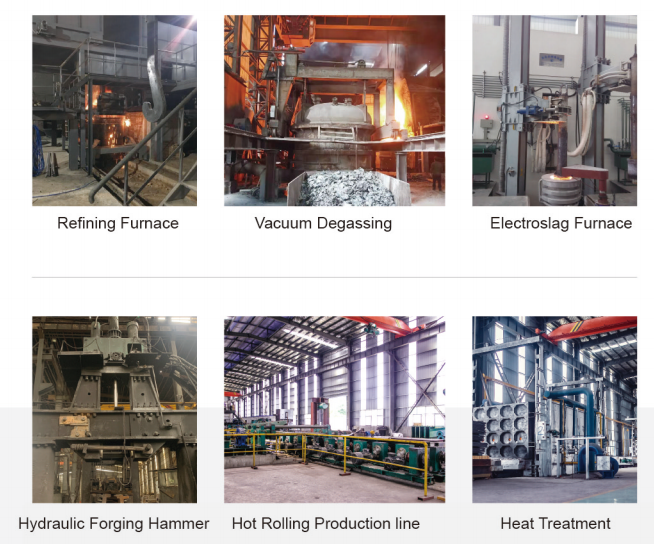

Hongxin Mold Tech Co.,Ltd. owns 1 set of Hot Rolling Production Line at size range flats 8-80*210-710mm, rounds 16-50mm Dia.

12 sets of Hydraulic Forging Hammers from Power 560kgs to 6000kgs which could cover flats 40-300*210-710mm.

8 sets of EF+LF+VD

5 sets of ESR

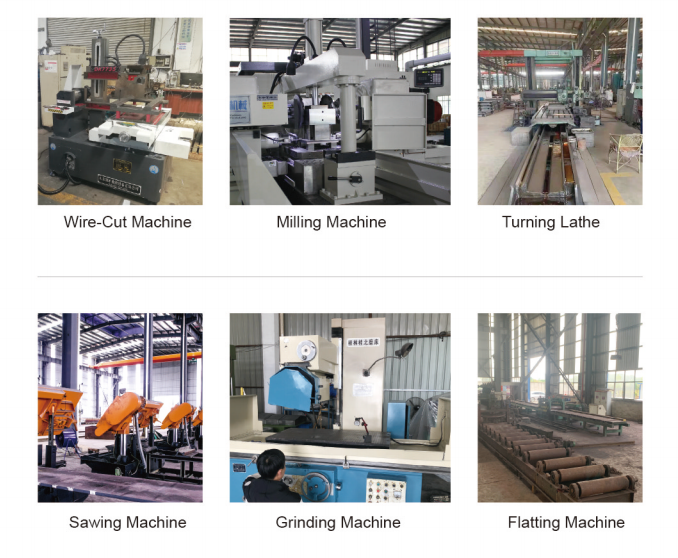

9 sets of Milling Machines

10 sets of Turning Lathes

6 sets of Precision Milling Machines.

![]() Standard GB:T 39733-2020 Recycling Iron-Steel Materials (English Version).pdf

Standard GB:T 39733-2020 Recycling Iron-Steel Materials (English Version).pdf

![]() Standard GB:T 39733-2020 再生钢铁原料.pdf

Standard GB:T 39733-2020 再生钢铁原料.pdf

CERTIFICATION: GB/T19001-2016/ISO9001:2015

Products' List

Q1:Are you trading company or manufacturer ?

We are the biggest tool steel factory at Daye &Huangshi. We can provide a wide range of steel products.

Q2:What is alloy steel round bar export packing?

Usually bundling for large diameter,small diameter bars in bulk or as customer's demand.

Q3.What is your MOQ?

We accept small order,if it is stock,any quantities can be accepted.

Q4.What is your lead time?

Depends actual order,around 20-35 days,or negotiation.

Q5.Can you supply sample?

Yes,we can.Sample fee according to your size.

Q6:What certificates do you have?

ISO, ABS, BV, CCS, Dnv, Lr, Gl, Mill Certificate

Q7: How can I get your quotation as soon as possible?

The email and fax will be checked within 24 hours,meanwhile,the Skype,Wechat and WhatsApp will be online in 24 hours.Please send us your requirement,we will work out a best price soon.