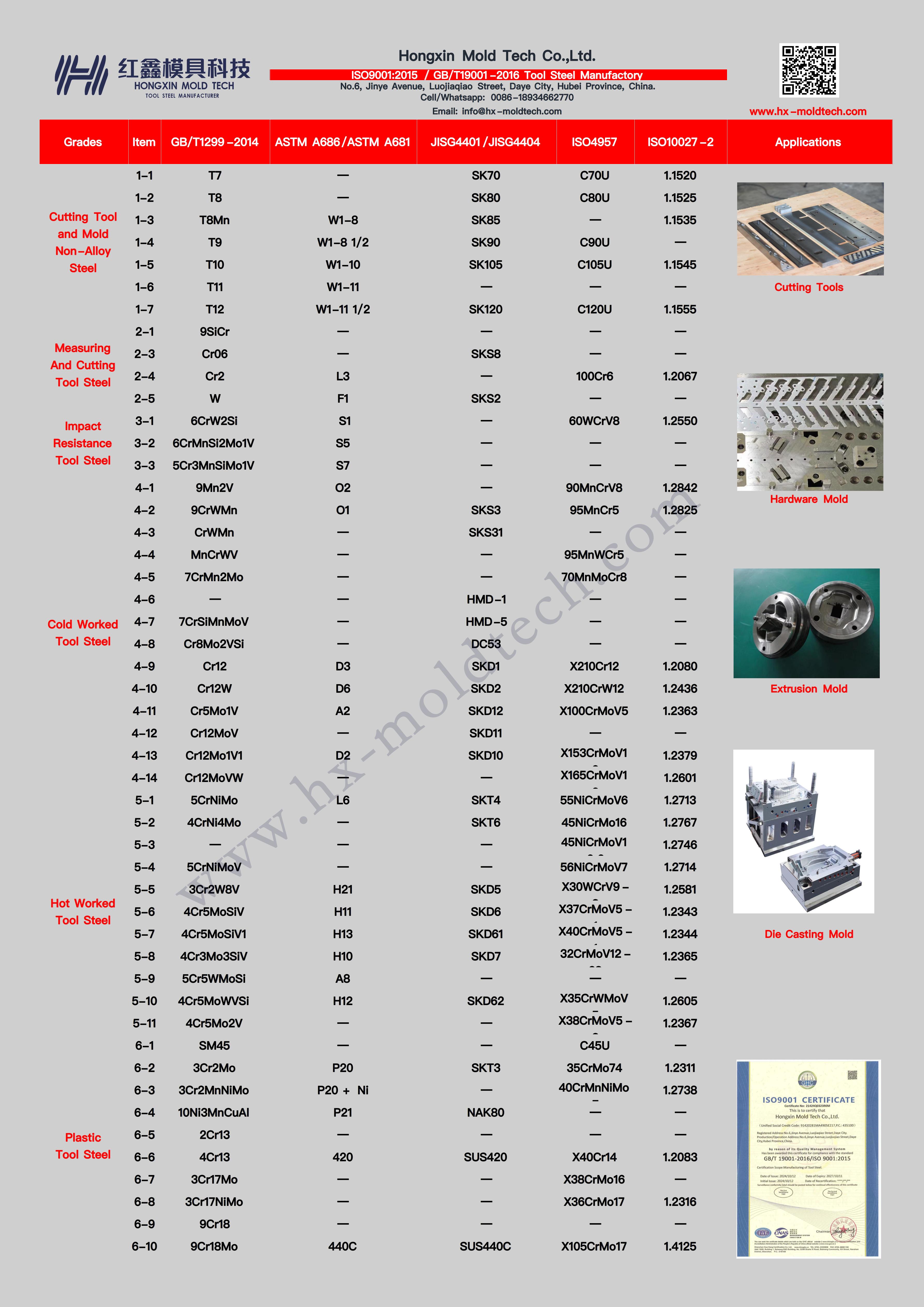

DC53 Cold Work Tool Steel

The utility of DC 53:

1. Excellent wear resistance: DC53 has a high level of chromium and carbon content, which gives it excellent wear resistance, making it ideal for applications where tools are subjected to abrasive wear.

2. Good toughness: DC53 also has good toughness, which allows it to withstand high impact loads without cracking or chipping. This makes it suitable for applications where tools are subjected to heavy use and high impact forces.

3. Easy machinability: DC53 is relatively easy to machine, which makes it easier to produce complex shapes and designs for cutting tools, dies, and molds.

4. Good dimensional stability: DC53 has good dimensional stability, which means that it maintains its shape and dimensions even under high temperatures and heavy loads. This makes it ideal for applications where precision and accuracy are crucial.

- HONGXIN

- DAYE

- 30 DAYS

- 8000T/MONTH

- Information

DC53 Cold Work Tool Steel

1: DC53 Steel Introduction

DC53 steel is a new type of cold working die steel modified SKD11, and its technical specification is listed in Japanese Industrial Standard (JIS) G4404. It overcomes the weakness of high temperature tempering hardness and toughness of SKD11, and will replace SKD11 in the field of general purpose and precision die. The toughness of DC53 is twice that of SKD11. The toughness of DC53 is more prominent in cold working die steel. The tool made of DC53 seldom has cracks and cracks, which greatly improves the service life. The DC53 tool steel has a uniform distribution of fine carbides. It has great galling and wear and fatigue resistance. It has also a High temper resistance to support PVD & nitride surface treatments. And it has Machining and grinding properties are superior to most other tool steels.

2: DC53 Steel Equivalent

| Country | China | Japan | Germany |

| Standard | GB/T | JIS G4404 | DIN |

| Grade | DC53 |

3: DC53 Steel Chemical Composition

| Grade | C | Mn | P | S | Si | Cr | Mo | |||||

| DC53 | 1.00 | 0.35 | 0.002 | 0.003 | 1.00 | 8.00 | 2.00 | |||||

4: DC53 Steel Mechanical Properties

The mechanical properties mainly include tensile strength, yield strength, elongation, area or reduction, hardness, impact value, non-metalic inclusion etc. Different heat treatment, the mechanical properties will be different, such as normalized, tempered, QT. If you want to know the properties, kindly contact the salesman.

5: DC53 Steel Overviews

| Size | Round | Dia 12-500mm | |

| Plate/Flat/Block | Thickness 8mm-300mm | ||

| Width 210mm-710mm | |||

| Process | EAF+LF+VD+Forged+Heat treatment(optional) | ||

| Heat treatment | Normalized ; Annealed ; Quenched ; Tempered | ||

| Surface condition | Black; Peeled; Polished; Machined; Grinded; Turned; Milled | ||

| Delivery condition | Forged; Hot rolled; Cold drawn | ||

| Test | Tensile strength, Yield strength, elongation, area of reduction, impact value, hardness, grain size, ultrasonic test, US inspection, magnetic particle testing, etc. | ||

| Payment terms | T/T;L/C;/Money gram/ Paypal | ||

| Trade terms | FOB; CIF; C&F; etc.. | ||

| Packing | Standard Packages, or as Customers Request | ||

| Delivery time | 30-45 days | ||

| Application | DC53 is used for precision stamping die (wire cutting precision punching die and punching die for various purposes), tools for plastic deformation of difficult-to-machine materials, die for cold forging, deep drawing and thread rolling, blanking die, cold forming die, cold drawing die, forming roll, punch. | ||

6: Heat Treatment

Forging

Slowly and uniformly Heat the DC53 tool steel to 700°C (1292°F),then rapidly heat the DC53 steel to 900-1040°C(1652-1904°F). After forging slowly cool down.

Annealing

Normal D53C annealing condition delivery, hardness 255HB MAX. When finished the DC53 Steel tool, then can heat treatment to appropriate hardness.

Hardening

Heat slowly the DC53 tool steel to 850°C(1562°F), Soak thoroughly at the temperature. the brought up to 1030°C(1886°F)oil quenching or air cool.

Tempering

Commonly performed DC53 Tempering is in a high Vacuum controlled convection furnace. The temper is perfect after Hardening. conducted as soon as the part can be hand at about 45° C (120° F) to 65° C (150° F). by High temperature tempering and hardening, hardness tool steel DC53 can reached 65 HRC MAX. common application ,we advice the Hardness no higher than 62HRC.

Heat Treatment

The DC53 Tool steel heat treatment process can be broken down into 4 segments, Hardening (quench) & Tempering.Annealing & Normalized.

7: Delivery Condition

For hot forged or hot rolled bar, usually the delivery condition is hot forged or rolled, annealed, rough turned.

For hot forged plate, usually the delivery condition is hot forged, annealed, milled surface.

For hot rolled plate, usually the delivery condition is hot rolled, annealed, black surface.

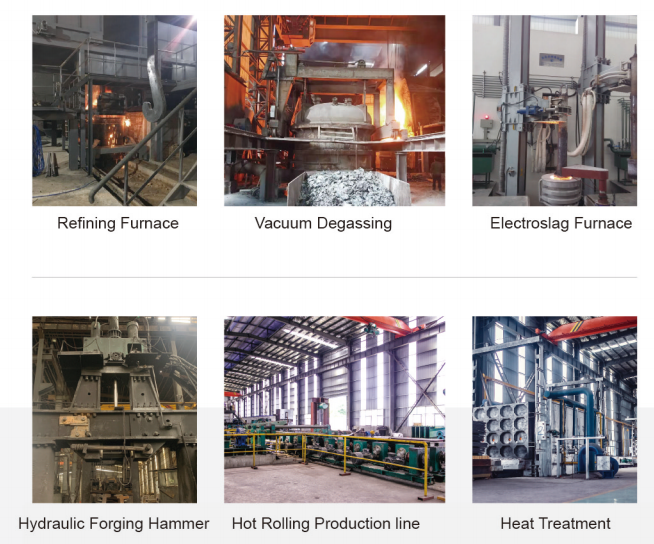

Hongxin Mold Tech Co.,Ltd. owns 1 set of Hot Rolling Production Line at size range flats 8-80*210-710mm, rounds 16-50mm Dia.

12 sets of Hydraulic Forging Hammers from Power 560kgs to 6000kgs which could cover flats 40-300*210-710mm.

8 sets of EF+LF+VD

5 sets of ESR

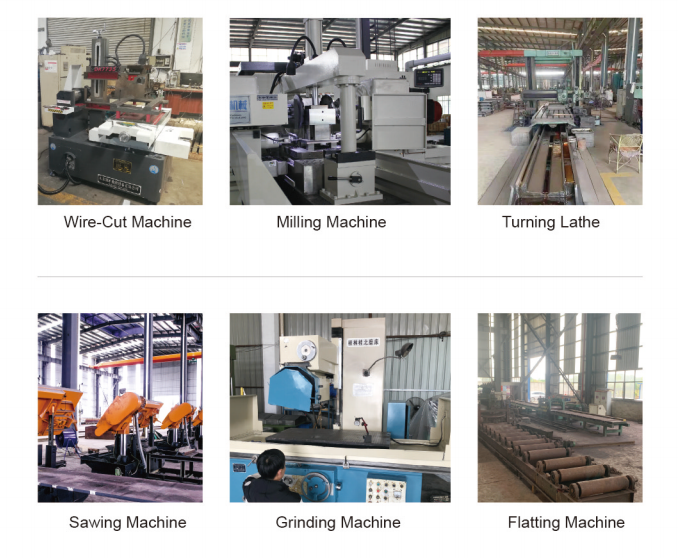

9 sets of Milling Machines

10 sets of Turning Lathes

6 sets of Precision Milling Machines.

CERTIFICATION: GB/T19001-2016/ISO9001:2015

Productions' List

Packaging & Shipping