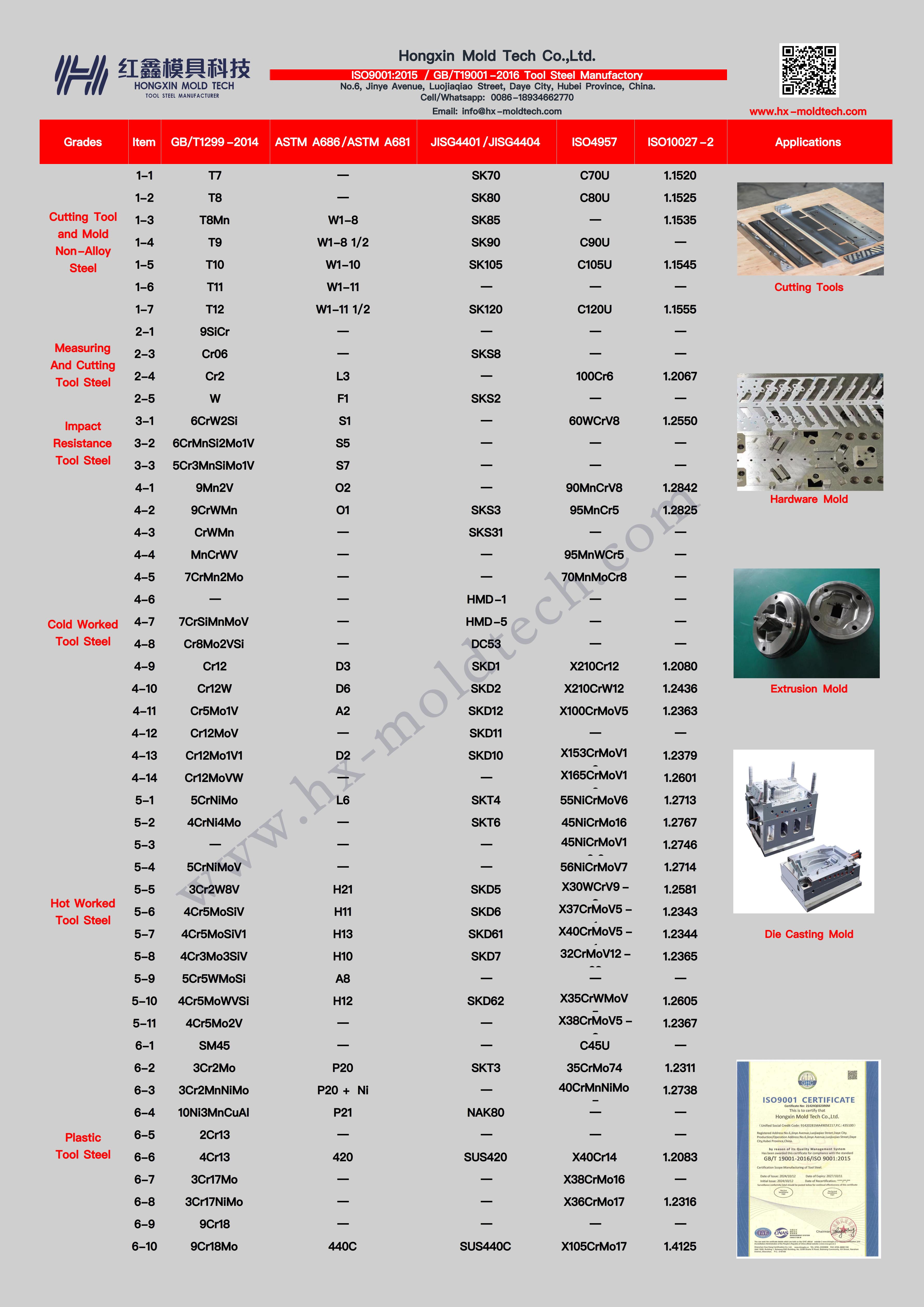

CrWMn Cold Work Tool Steel

CrWMn is the most commonly used high carbon alloy tool steel for making molds.

- HONGXIN

- DAYE

- 30 DAYS

- 8000T/MONTH

- Information

CrWMn Cold Work Tool Steel

1: CrWMn Steel Introduction

CrWMn is the most commonly used high carbon alloy tool steel for making molds. CrWMn steel has high hardenability. Since tungsten forms carbides, this steel has more excess carbides and higher hardness and wear resistance than chromium steel and 9SiCr steel after quenching and low-temperature tempering.

In addition, tungsten also helps to preserve fine grains, so that the steel gets better toughness. Therefore, the cutting tool made of CrWMn steel has less chipping and can maintain the shape and size of the cutting edge.

However, steel is more sensitive to the formation of carbide networks. The existence of such a network causes the blade edge to be flaking off, thus shortening the service life of the tool.

Therefore, steels with carbide meshes must be based on their severity. Forging and normalizing. This type of steel is used to make tools that do not heat up sharply at the time of work and require gauges and cutting tools that do not deform when quenched, such as making knives, filament cones, long reamers, special milling cutters, dies, and other types of special tools. Tools, and cutters for cutting soft non-metallic materials.

2: CrWMn Steel Equivalent

| USA | Germany | Japan | France | European | Italy | Spain | China | Sweden | Bulgaria | Hungary | Poland | Romania | South Korea | ||

| - | DIN,WNr | JIS | AFNOR | EN | UNI | UNE | GB | SS | BDS | MSZ | PN | STAS | KS | ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3: CrWMn Steel Chemical Composition

| Grade | C | Mn | P | S | Si | Cr | W | Cu | |||||

| CrWMn | 0.90-1.05 | 0.80-1.10 | ≤0.030 | ≤0.030 | 0.10-0.40 | 0.90-1.20 | 1.20-1.60 | ≤0.30 | |||||

4: CrWMn Steel Mechanical Properties

| Yield Rp0.2 (MPa) | Tensile Rm (MPa) | Impact KV/Ku (J) | Elongation A (%) | Reduction in cross section on fracture Z (%) | As-Heat-Treated Condition | Brinell hardness (HBW) |

|---|---|---|---|---|---|---|

| 834 (≥) | 364 (≥) | 32 | 33 | 23 | Solution and Aging, Annealing, Ausaging, Q+T,etc | 414 |

5: CrWMn Steel Overviews

| Size | Round | Dia 12-500mm | |

| Plate/Flat/Block | Thickness 8mm-300mm | ||

| Width 210mm-710mm | |||

| Process | EAF+LF+VD+Forged+Heat treatment(optional) | ||

| Heat treatment | Normalized ; Annealed ; Quenched ; Tempered | ||

| Surface condition | Black; Peeled; Polished; Machined; Grinded; Turned; Milled | ||

| Delivery condition | Forged; Hot rolled; Cold drawn | ||

| Test | Tensile strength, Yield strength, elongation, area of reduction, impact value, hardness, grain size, ultrasonic test, US inspection, magnetic particle testing, etc. | ||

| Payment terms | T/T;L/C;/Money gram/ Paypal | ||

| Trade terms | FOB; CIF; C&F; etc.. | ||

| Packing | Standard Packages, or as Customers Request | ||

| Delivery time | 30-45 days | ||

| Application | DC53 is used for precision stamping die (wire cutting precision punching die and punching die for various purposes), tools for plastic deformation of difficult-to-machine materials, die for cold forging, deep drawing and thread rolling, blanking die, cold forming die, cold drawing die, forming roll, punch. | ||

6: Delivery Condition

For hot forged or hot rolled bar, usually the delivery condition is hot forged or rolled, annealed, rough turned.

For hot forged plate, usually the delivery condition is hot forged, annealed, milled surface.

For hot rolled plate, usually the delivery condition is hot rolled, annealed, black surface.

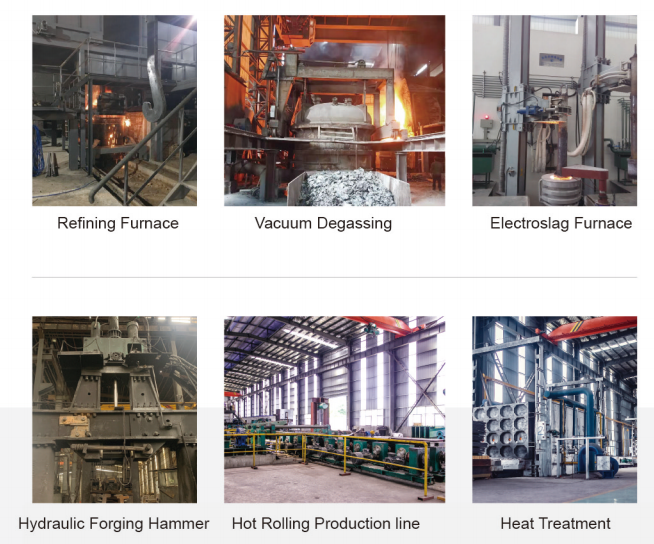

Hongxin Mold Tech Co.,Ltd. owns 1 set of Hot Rolling Production Line at size range flats 8-80*210-710mm, rounds 16-50mm Dia.

12 sets of Hydraulic Forging Hammers from Power 560kgs to 6000kgs which could cover flats 40-300*210-710mm.

8 sets of EF+LF+VD

5 sets of ESR

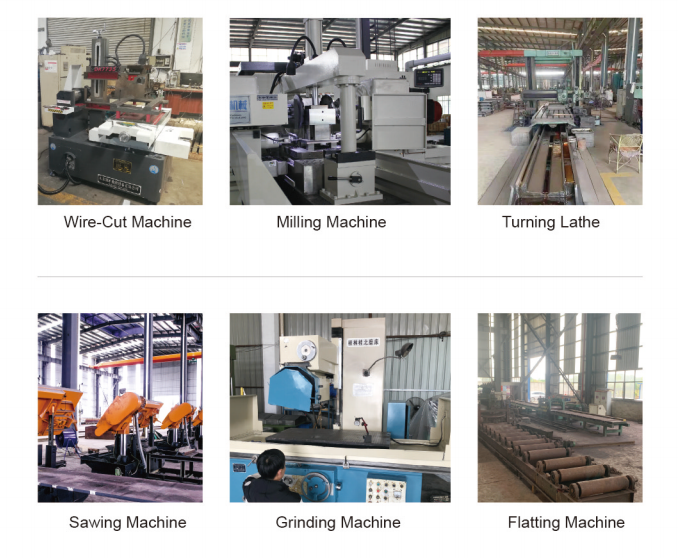

9 sets of Milling Machines

10 sets of Turning Lathes

6 sets of Precision Milling Machines.

CERTIFICATION: GB/T19001-2016/ISO9001:2015

Products' List

Packaging & Shipping