What Hardness Is Tool Steel

2024-09-18 15:07In the realm of metalworking, the selection of the right tool steel is paramount for achieving optimal performance and durability. Tool steel hardness is a critical characteristic that defines its suitability for specific applications. This article explores the concept of tool steel hardness and introduces Hongxin, a brand known for its high-quality DC53 cold work tool steel.

What Hardness is Tool Steel?

Hardness is a measure of a material's resistance to localized deformation, especially plastic deformation, indentation, or scratch. In the context of tool steels, hardness is crucial because it directly impacts the tool's ability to maintain its edge and resist wear during use. Tool steels are classified based on their hardness, which can range widely depending on the specific alloy and heat treatment applied.

Hardness Measurement: The hardness of tool steels is typically measured using the Rockwell C scale (HRC). This scale is commonly used because it provides a direct indication of the material's ability to resist indentation. Higher HRC values indicate greater hardness.

Common Hardness Levels: Most tool steels achieve hardness levels between 58 HRC and 65 HRC after proper heat treatment. However, some specialized grades can reach even higher hardness levels, sacrificing some toughness for increased wear resistance.

Factors Influencing Hardness: The hardness of tool steel is influenced by several factors, including the chemical composition of the alloy, the cooling rate during quenching, and the tempering process. Alloying elements like chromium, molybdenum, tungsten, and vanadium contribute to increased hardness and wear resistance.

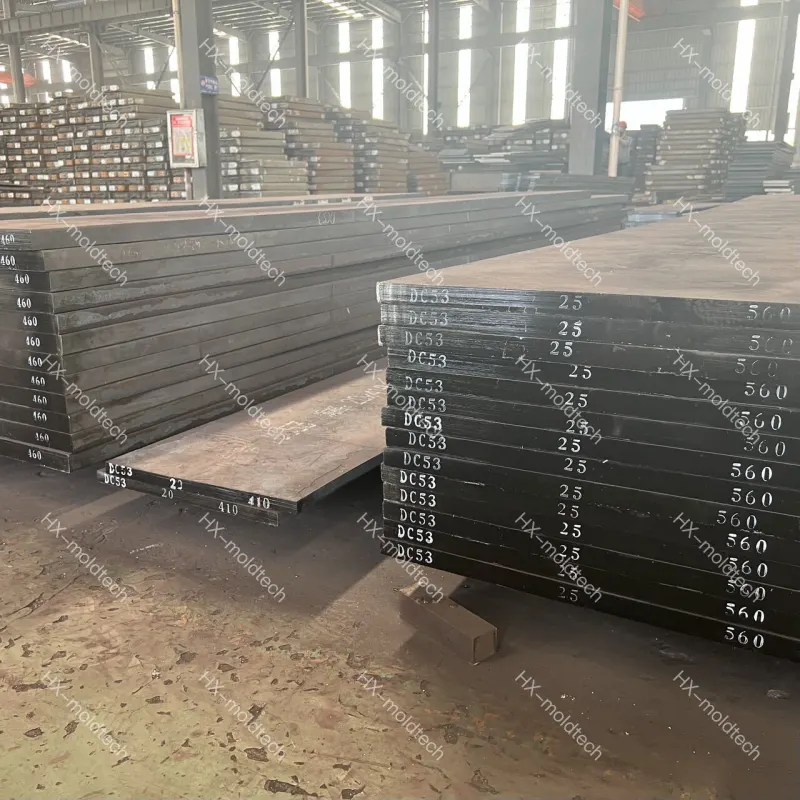

Hongxin: DC53 Cold Work Tool Steel

Hongxin is a reputable brand that specializes in the production of high-quality tool steels, with a particular emphasis on the DC53 grade cold work tool steel. Known for its balance of hardness and toughness, DC53 is a preferred choice for applications requiring both sharp edges and resistance to chipping.

Chemical Composition: DC53 contains a carefully balanced mix of alloying elements, including chromium, molybdenum, and vanadium. These elements contribute to the steel's excellent wear resistance and toughness, making it suitable for cold work applications such as punches, dies, and cutting tools.

Heat Treatment: The heat treatment process for DC53 is critical to achieving its optimal hardness. Typically, the steel is austenitized at temperatures around 1020°C and then air-cooled or oil-quenched. Subsequent tempering treatments further refine the microstructure and stabilize the hardness level, typically bringing it to a range of 58-62 HRC.

Applications: The high hardness and wear resistance of DC53 make it ideal for use in cold stamping dies, shearing blades, and other applications where the tool is subjected to high compression and abrasion. Its ability to maintain a sharp edge even under demanding conditions is particularly valued in the manufacturing industry.

Benefits of Using Hongxin's DC53 Tool Steel

By choosing Hongxin's DC53 cold work tool steel, manufacturers can benefit from:

Enhanced Performance: The high hardness of DC53 contributes to longer tool life and reduced downtime for maintenance and replacement.

Reliability: The consistent quality of Hongxin's tool steel ensures that tools maintain their integrity and performance across multiple production cycles.

Versatility: While DC53 is designed for cold work applications, its properties also make it suitable for certain hot work scenarios, extending its usability in diverse industrial settings.

The hardness of tool steel is a key factor in determining its suitability for specific applications. Hongxin's DC53 cold work tool steel exemplifies the balance between hardness and toughness required for demanding industrial uses. By investing in high-quality tool steels like those offered by Hongxin, manufacturers can achieve improved efficiency, reduced costs, and enhanced product quality. Whether you are designing new tools or upgrading existing ones, considering the hardness and properties of the tool steel is essential for success.