What Are The Properties Of Gb/T Cr12mo1v1 Cold Working Die Steel Parts

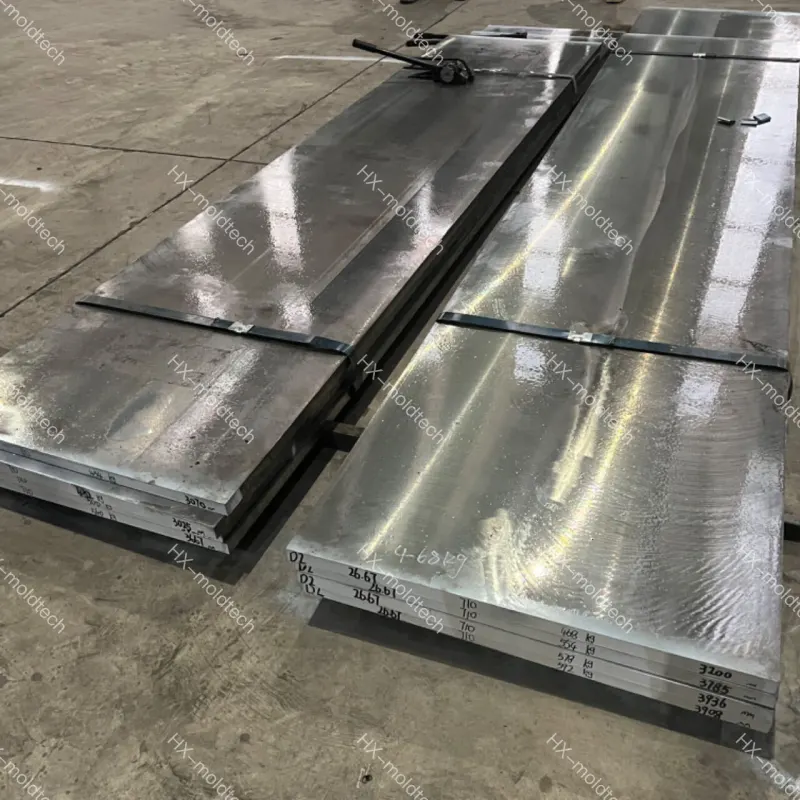

2024-09-10 16:48In the manufacturing industry, the choice of material for tooling and dies plays a crucial role in determining the quality and durability of the end products. Among the many alloys available, GB/T Cr12Mo1V1 cold working die steel has gained recognition for its superior properties and performance. This article will explore the properties of GB/T Cr12Mo1V1 cold working die steel parts and the characteristics of this material when used in mold applications, highlighting Hongxin as a leading provider of these materials.

What Are the Properties of GB/T Cr12Mo1V1 Cold Working Die Steel Parts?

GB/T Cr12Mo1V1 is a high-carbon, high-chromium alloy tool steel designed specifically for cold work applications. Its properties make it an ideal choice for demanding manufacturing processes where wear resistance, toughness, and dimensional stability are critical. Here are some key properties of GB/T Cr12Mo1V1 cold working die steel parts offered by Hongxin:

High Wear Resistance

One of the standout features of GB/T Cr12Mo1V1 is its exceptional wear resistance. This is due to the high chromium content, which forms a hard layer on the surface of the steel parts, protecting them against abrasion and wear during operation.

Excellent Hardness

The high carbon content contributes to the hardness of the steel, which can be further enhanced through heat treatment processes. Hongxin's GB/T Cr12Mo1V1 steel parts can achieve a hardness level of around 60-63 HRC after proper hardening and tempering, making them suitable for applications requiring high strength and durability.

Good Toughness

Despite its high hardness, GB/T Cr12Mo1V1 maintains good toughness, which is vital for preventing brittle fracture during use. This balance between hardness and toughness is achieved through controlled alloying and heat treatment processes, ensuring that the steel can withstand the impact and stress encountered in cold working operations.

Dimensional Stability

The material exhibits excellent dimensional stability after heat treatment, meaning that the parts maintain their shape and size despite changes in temperature. This characteristic is crucial for precision parts where tolerances must be strictly maintained.

GB/T Cr12Mo1V1 Mold Steel Characteristics

When it comes to mold-making, the characteristics of the steel used can significantly influence the lifespan and efficiency of the molds produced. Hongxin's GB/T Cr12Mo1V1 mold steel possesses several advantageous characteristics:

Corrosion Resistance

Due to the presence of chromium, GB/T Cr12Mo1V1 mold steel has a degree of corrosion resistance, which is beneficial for molds exposed to corrosive environments or materials. This property helps extend the service life of the molds and reduces maintenance costs.

Machinability

Although high-carbon and high-chromium steels can be challenging to machine, Hongxin's GB/T Cr12Mo1V1 steel is designed with machinability in mind. The steel can be machined to tight tolerances, allowing for intricate designs and complex shapes required in modern mold-making.

Heat Treatment Response

The alloy responds well to heat treatment, achieving a uniform hardness throughout the cross-section of the part. This uniformity is critical for maintaining the integrity of the mold during high-volume production runs.

Weldability

In cases where repairs or modifications are necessary, GB/T Cr12Mo1V1 steel can be welded with relative ease. Proper preheating and post-weld heat treatment can help prevent cracking and ensure a strong bond between the weld and the base material.

Hongxin's GB/T Cr12Mo1V1 cold working die steel and mold steel are engineered to meet the rigorous demands of the manufacturing industry. With properties such as high wear resistance, excellent hardness, good toughness, and dimensional stability, these materials provide a reliable foundation for tools and molds that require exceptional performance and durability. Whether you're involved in cold working operations or mold-making, choosing Hongxin's GB/T Cr12Mo1V1 steel ensures that you have a material capable of delivering on the quality and longevity your applications demand.