DIN 1.2826 / 60MnSiCr4 Cold Work Tool Steel

Impact Resistance & Durability

DIN 1.2826’s high manganese content (0.80-1.10%) ensures exceptional toughness, making it ideal for tools like chisels and agricultural blades that face repetitive impact. Its Charpy impact values (20-30 J) surpass conventional high-carbon steels like O1.

Simplified Machinability

In the annealed state (≤229 HB), the steel exhibits excellent machinability and grindability, reducing production time for complex geometries. Minimal distortion during heat treatment ensures dimensional accuracy for precision tools.

Cost-Effective Versatility

From industrial springs to forming dies, DIN 1.2826 adapts to diverse applications. Its lower alloy content reduces material costs while maintaining sufficient wear resistance for medium-duty tasks, ideal for small-scale manufacturers.

- HONGXIN

- 中国

- 30DAYS

- 8000TONS/MONTH

- Information

DIN 1.2826 (60MnSiCr4) Tool Steel Overview

1.DIN 1.2826 (60MnSiCr4) Tool Steel Introduction

DIN 1.2826 (60MnSiCr4) is a manganese-silicon-chromium alloyed cold work tool steel renowned for its balanced toughness, moderate wear resistance, and cost-effectiveness. With a composition of 0.55-0.65% carbon, 0.80-1.10% manganese, and 0.30-0.60% chromium, it achieves a hardness of 54-58 HRC after heat treatment. Its design prioritizes applications requiring shock resistance, such as blanking dies, agricultural tools, and industrial springs. Widely used in machinery, automotive, and tooling industries, DIN 1.2826 offers a practical balance between performance and affordability for medium-duty tooling.

2. DIN 1.2826 Tool Steel Supply Range

| Size | Round | Dia 12-500mm |

| Plate/Flat/Block | Thickness 8mm-300mm | |

| Width 210mm-710mm | ||

| Process | EAF+LF+VD+Forged+Heat treatment(optional),or ESR Melting Process |

3. DIN 1.2826 Tool Steel Chemical Composition

| Grade | C | Si | Mn | P | S | Cr |

| 60MnSiCr4 | 0.58-0.65 | 0.8-1 | 0.8-1.2 | 0-0.03 | 0-0.03 | 0.2-0.4 |

4. DIN 1.2826 Tool Steel Physical & Mechanical Properties

Physical Properties

| Property | Metric Units |

|---|---|

| Density | 7.85 g/cm³ |

| Thermal Expansion (20-100°C) | 11.5×10⁻⁶/°C |

| Thermal Conductivity | 32 W/(m·K) |

Mechanical Properties

| Property | Metric Units |

|---|---|

| Hardness (Quenched & Tempered) | 54-58 HRC |

| Tensile Strength | 1600-1800 MPa |

| Impact Toughness (Charpy) | 20-30 J |

5. DIN 1.2826 Tool Steel Heat Treatment

Annealing: Heat to 750-780°C, slow cool to ≤500°C. Final hardness: ≤229 HB.

Quenching: Oil quench from 820-860°C to achieve 54-58 HRC.

Tempering: Temper at 200-400°C for 1-2 hours. Double tempering recommended for stress relief.

Annealing: Heat to 750-780°C, slow cool to ≤500°C. Final hardness: ≤229 HB.

Quenching: Oil quench from 820-860°C to achieve 54-58 HRC.

Tempering: Temper at 200-400°C for 1-2 hours. Double tempering recommended for stress relief.

7. Key Advantages of DIN 1.2826 Steel

Balanced Toughness & Wear Resistance: Ideal for tools subjected to both impact and abrasion.

Ease of Machining: Low annealing hardness (<229 HB) simplifies grinding and shaping.

Economic Efficiency: Lower cost than high-alloy steels, suitable for small-to-medium production batches.

5. Delivery condition

For hot forged or hot rolled bar, usually the delivery condition is hot forged or rolled, annealed, rough turned.

For hot forged plate, usually the delivery condition is hot forged, annealed, milled surface.

For hot rolled plate, usually the delivery condition is hot rolled, annealed, black surface.

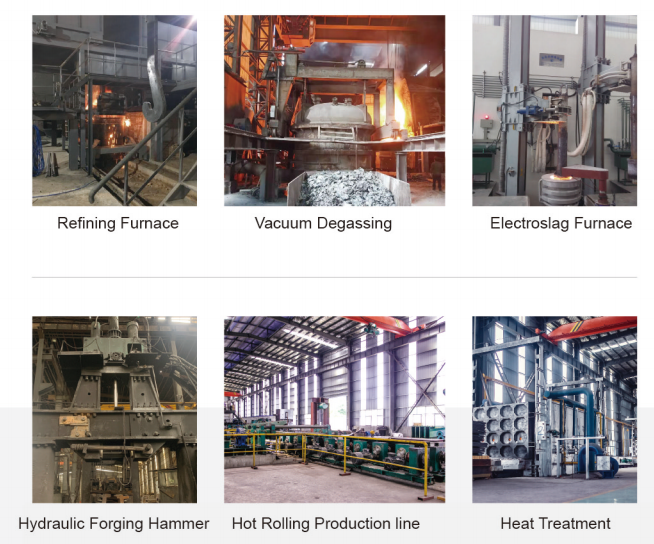

Hongxin Mold Tech Co.,Ltd. owns 1 set of Hot Rolling Production Line at size range flats 8-80*210-710mm, rounds 16-50mm Dia.

12 sets of Hydraulic Forging Hammers from Power 560kgs to 6000kgs which could cover flats 40-300*210-710mm.

8 sets of EF+LF+VD

5 sets of ESR

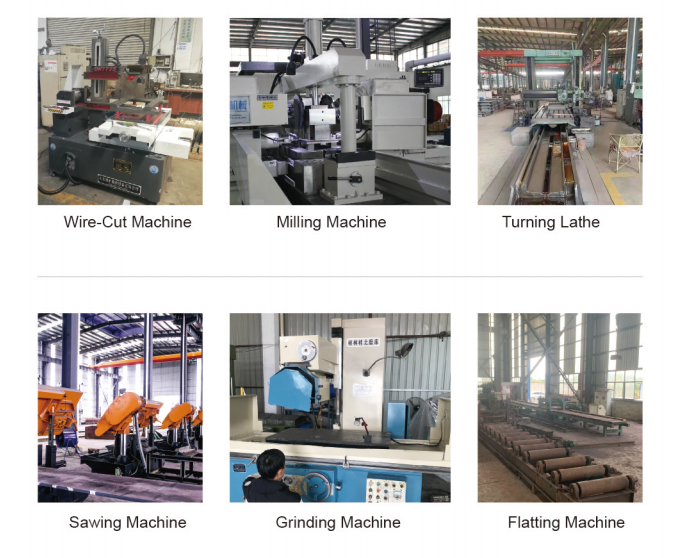

9 sets of Milling Machines

10 sets of Turning Lathes

6 sets of Precision Milling Machines.

CERTIFICATION: GB/T19001-2016/ISO9001:2015

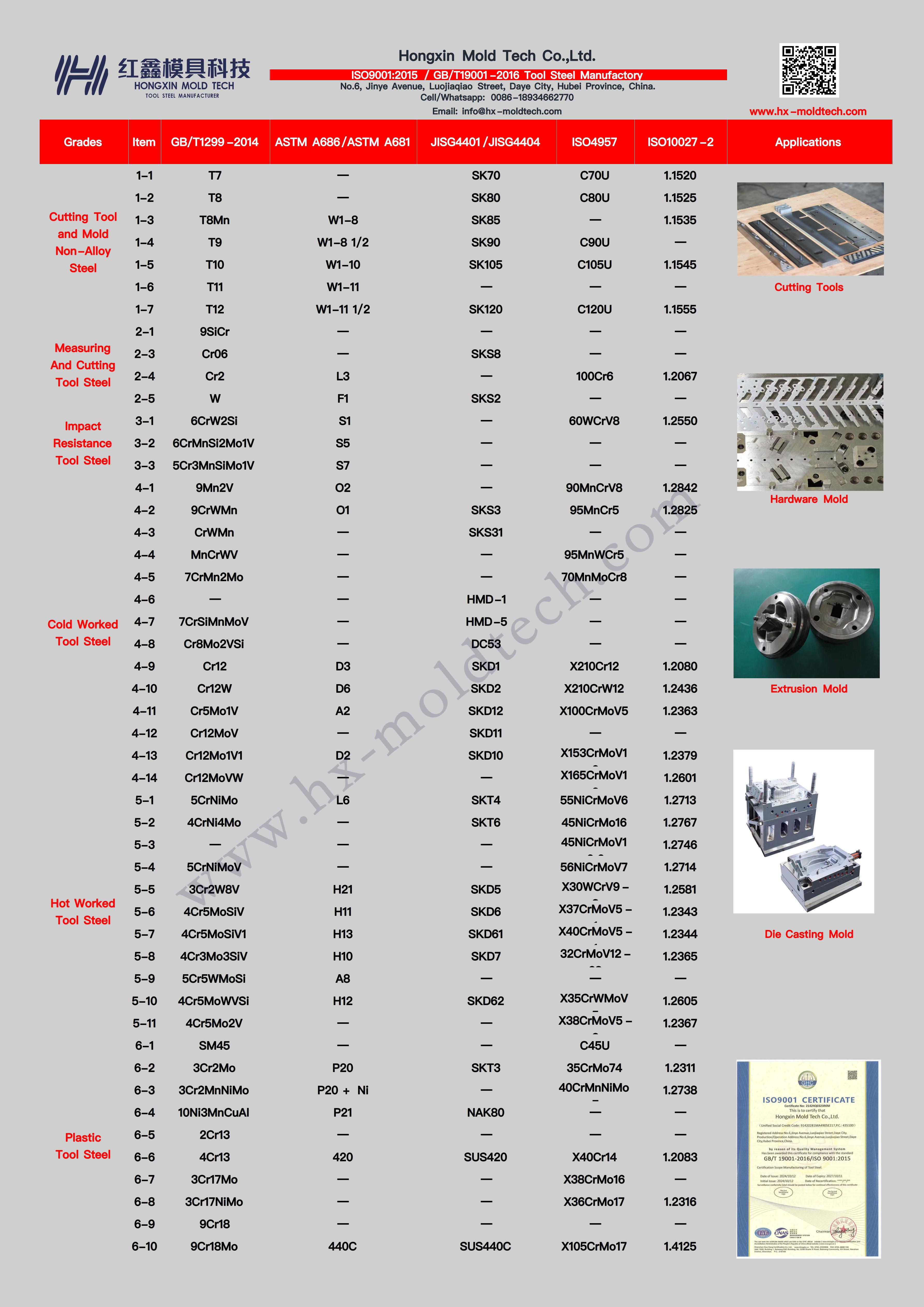

Products' List

Q1:Are you trading company or manufacturer ?

We are the largest tool steel manufacturer in Daye,Huangshi,Hubei,China. we can provide a wide range of steel products.

Q2:What is alloy steel round bar export packing?

Usually bundling for large diameter,small diameter bars in bulk or as customer's demand.

Q3.What is your MOQ?

We accept small order,if it is stock,any quantities can be accepted.

Q4.What is your lead time?

Depends actual order,around 20-35 days,or negotiation.

Q5.Can you supply sample?

Yes,we can.Sample fee according to your size.

Q6:What certificates do you have?

ISO, ABS, BV, CCS, Dnv, Lr, Gl, Mill Certificate

Q7: How can I get your quotation as soon as possible?

The email will be checked within 24 hours,meanwhile,the Skype,Wechat and WhatsApp will be online in 24 hours.Please send us your requirement,we will work out a best price soon.