DIN 1.2714/55NiCrMoV7 Hot Worked Tool Steel

Superior High-Temperature Performance

DIN 1.2714 retains 45 HRC at 650°C, offering 30% longer thermal fatigue life than H13. This makes it ideal for aluminum/zinc die-casting and hot forging dies under cyclic thermal stress.

Precision Machinability & Surface Finish

In the annealed state (≤260 HB), DIN 1.2714 exhibits excellent machinability. Its fine-grained structure allows mirror-like polishing, critical for plastic injection molds requiring high gloss.

Versatility & Cost-Effectiveness

From heavy-duty stamping tools to aerospace engine parts, DIN 1.2714 delivers reliable performance. Its cost efficiency and adaptability make it a top choice for medium-scale production and complex tooling.

- HONGXIN

- 中国

- 30DAYS

- 8000TONS/MONTH

- Information

Comprehensive Guide to DIN 1.2714 Hot Work Tool Steel

1. DIN 1.2714(55NiCrMoV7) steel introduction

DIN 1.2714 (56NiCrMoV7) is a high-performance hot work tool steel under the German DIN standard. With a composition of 0.50-0.60% carbon, 1.50-1.80% nickel, and 1.00-1.30% chromium, it achieves a hardness of 52-54 HRC after heat treatment. Its excellent thermal stability (retains 45 HRC at 650°C) and uniform microstructure make it ideal for hot forging dies, die-casting molds, and aerospace components. Widely used in automotive, metalworking, and heavy machinery industries, DIN 1.2714 balances durability and cost-effectiveness for high-temperature applications.

| Heat treatment | Normalized ; Annealed ; Quenched ; Tempered | ||

| Surface condition | Black; Peeled; Polished; Machined; Grinded; Turned; Milled | ||

| Delivery condition | Forged; Hot rolled; Cold drawn | ||

| Test | Tensile strength, Yield strength, elongation, area of reduction, impact value, hardness, grain size, ultrasonic test, US inspection, magnetic particle testing, etc. | ||

| Payment terms | T/T;L/C;/Money gram/ Paypal | ||

| Trade terms | FOB; CIF; C&F; etc.. | ||

| Packing | Standard Packages, or as Customers Request | ||

| Delivery time | 30-45 days | ||

| Application | DIN 1.2714 tool steel are suitable for the cutting tool, cold/heat distortion mould and measuring implements, and further to manufacture the piston, valve, valve seat of fuel pump of diesel engine, Cutting tools, Mechanical parts, Air hammer tools, Piercing tools. | ||

2. DIN 1.2714 Tool Steel Supply Range

| Size | Round | Dia 12-500mm | |

| Plate/Flat/Block | Thickness 8mm-300mm | ||

| Width 210mm-710mm | |||

| Process | EAF+LF+VD+Forged+Heat treatment(optional) | ||

3. DIN 1.2714 Tool Steel Chemical Composition & Global Equivalents

| Country | China | Japan | Germany | USA | UK |

| Standard | GB/T 1299 | JIS G4404 | DIN EN ISO4957 | ASTM A681 | BS 4659 |

| Grade | 5CrNiMoV | 1.2714 | 6F3 |

| Grade | C | Si | Mn | P | NI | Cr | V | Mo | |||||||

| DIN 1.2714 | 0.50 | 0.60 | 0.10 | 0.40 | 0.65 | 0.95 | 0.03 | 1.50 | 1.80 | 1.00 | 1.20 | 0.07 | 0.12 | 0.45 | 0.55 |

| ASTM 6F3 | 0.50 | 0.60 | 0.10 | 0.40 | 0.65 | 0.95 | 0.03 | 1.50 | 1.80 | 1.00 | 1.20 | 0.07 | 0.12 | 0.45 | 0.55 |

4. DIN 1.2714 Tool Steel Physical & Mechanical Properties

Physical Properties

| Property | Metric Units |

|---|---|

| Density | 7.8 g/cm³ |

| Thermal Expansion (20-100°C) | 12.5×10⁻⁶/°C |

| Thermal Conductivity | 35.9 W/(m·K) |

Mechanical Properties

| Property | Metric Units |

|---|---|

| Tensile Strength | ≥816 MPa |

| Yield Strength | ≥977 MPa |

| Hardness (Quenched & Tempered) | 52-54 HRC |

| Impact Toughness (Charpy) | 23-33 J |

4. DIN 1.2714 Tool Steel Physical & Mechanical Properties

Physical Properties

| Property | Metric Units |

|---|---|

| Density | 7.8 g/cm³ |

| Thermal Expansion (20-100°C) | 12.5×10⁻⁶/°C |

| Thermal Conductivity | 35.9 W/(m·K) |

Mechanical Properties

| Property | Metric Units |

|---|---|

| Tensile Strength | ≥816 MPa |

| Yield Strength | ≥977 MPa |

| Hardness (Quenched & Tempered) | 52-54 HRC |

| Impact Toughness (Charpy) | 23-33 J |

6. DIN 1.2714 Tool Steel Applications

Hot Work Tools: Hot forging dies, aluminum/zinc die-casting molds, copper alloy extrusion dies.

Industrial Tools: Hot rollers, hot punches, heavy-duty stamping dies.

Aerospace: Engine components, high-stress transmission parts.

Automotive: Crankshafts, gearbox parts, and high-temperature components.

Why Choose DIN 1.2714?

Resists oxidation and corrosion up to 650°C.

30% longer thermal fatigue life compared to H13.

Key Advantages of DIN 1.2714 Steel

High Thermal Resistance: Maintains 45 HRC at 650°C, ideal for cyclic thermal loads (e.g., die-casting molds).

Deep Hardenability: Air cooling forms martensite uniformly, suitable for large/complex tools.

Cost Efficiency: Excellent machinability in annealed state reduces processing costs for medium-batch production.

7. Features and classifications

Hot-work die divides into several main types, such as hammer forging, die forging, extrusion and die casting, including hot forging die, press machine forging die, stamping die, hot-extrusion die, metal die-casting mould. Heat distortion mould not only supports huge mechanical stress, but also thermal stress during working repeatedly. Hot-work die steel should have not only high hardness, red hardness, abrasion resistance, toughness, but also have excellent high temperature strength, thermal fatigue stability, thermal conductivity, upper harden-ability for guaranteeing the whole cross section with consistent mechanical property.

8. Delivery condition

For hot forged or hot rolled bar, usually the delivery condition is hot forged or rolled, annealed, rough turned.

For hot forged plate, usually the delivery condition is hot forged, annealed, milled surface.

For hot rolled plate, usually the delivery condition is hot rolled, annealed, black surface.

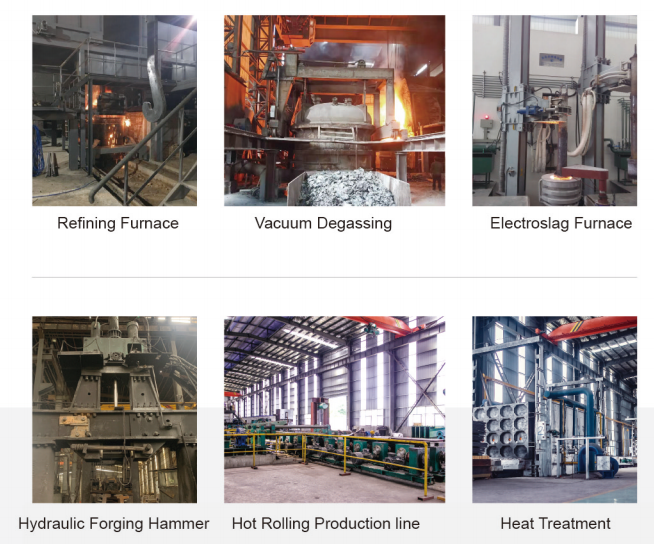

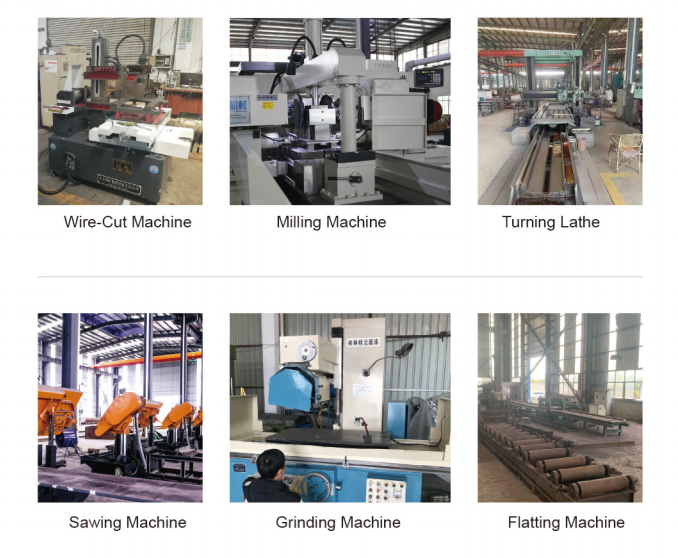

Hongxin Mold Tech Co.,Ltd. owns 1 set of Hot Rolling Production Line at size range flats 8-80*210-710mm, rounds 16-50mm Dia.

12 sets of Hydraulic Forging Hammers from Power 560kgs to 6000kgs which could cover flats 40-300*210-710mm.

8 sets of EF+LF+VD

5 sets of ESR

9 sets of Milling Machines

10 sets of Turning Lathes

6 sets of Precision Milling Machines.

CERTIFICATION: GB/T19001-2016/ISO9001:2015

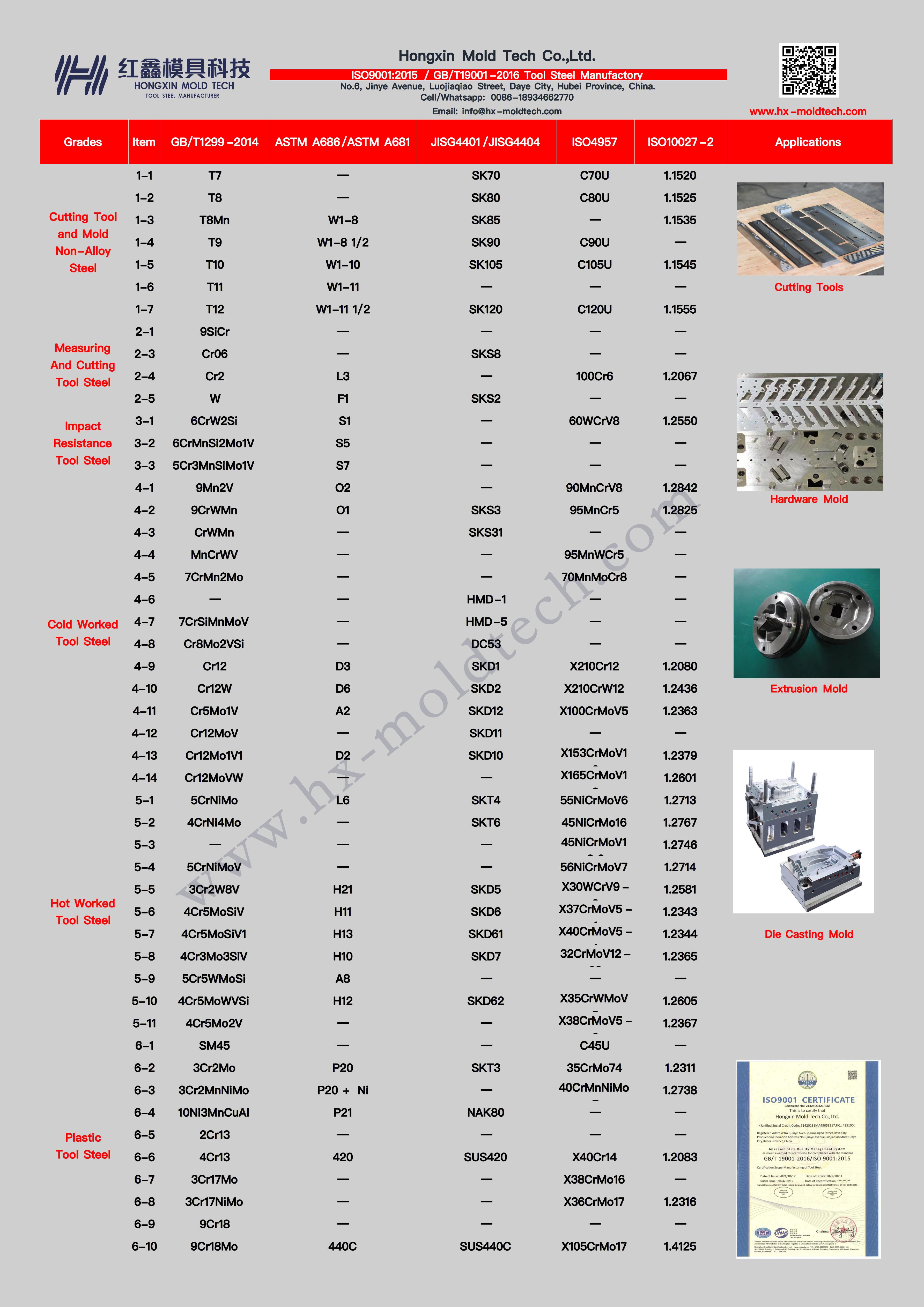

Products' List

Q1:Are you trading company or manufacturer ?

We are the biggest tool steel factory at Daye & Huangshi. We can provide a wide range of steel products.

Q2:What is alloy steel round bar export packing?

Usually bundling for large diameter,small diameter bars in bulk or as customer's demand.

Q3.What is your MOQ?

We accept small order,if it is stock,any quantities can be accepted.

Q4.What is your lead time?

Depends actual order,around 20-35 days,or negotiation.

Q5.Can you supply sample?

Yes,we can.Sample fee according to your size.

Q6:What certificates do you have?

ISO, ABS, BV, CCS, Dnv, Lr, Gl, Mill Certificate

Q7: How can I get your quotation as soon as possible?

The email and fax will be checked within 24 hours,meanwhile,the Skype,Wechat and WhatsApp will be online in 24 hours.Please send us your requirement,we will work out a best price soon.